ASME P-Numbers

P-Number Groupings per ASME Section IX

WHAT IS A P-NUMBER?

A P-Number is an alphanumeric designation assigned to a group of base metals. These materials are grouped based on their similar weldability, mechanical characteristics, and alloy types such as Carbon Steel, Low Alloy Steel or Chrome Steel, Stainless Steel, Aluminum, and Nickel for example.

P-Numbers are assigned to base metals to reduce the number of welding and brazing procedure qualifications required to perform work.

With a fundamental understanding this system can be very useful in simplifying the determination of who is qualified to perform joining work within the ASME codes.

P-Numbers are made of numbers and sometimes include letters. It is important to note that each P-Number is considered a separate and unique number. For example, base metals assigned P-No. 5A are an entirely different group than P-No. 5B.

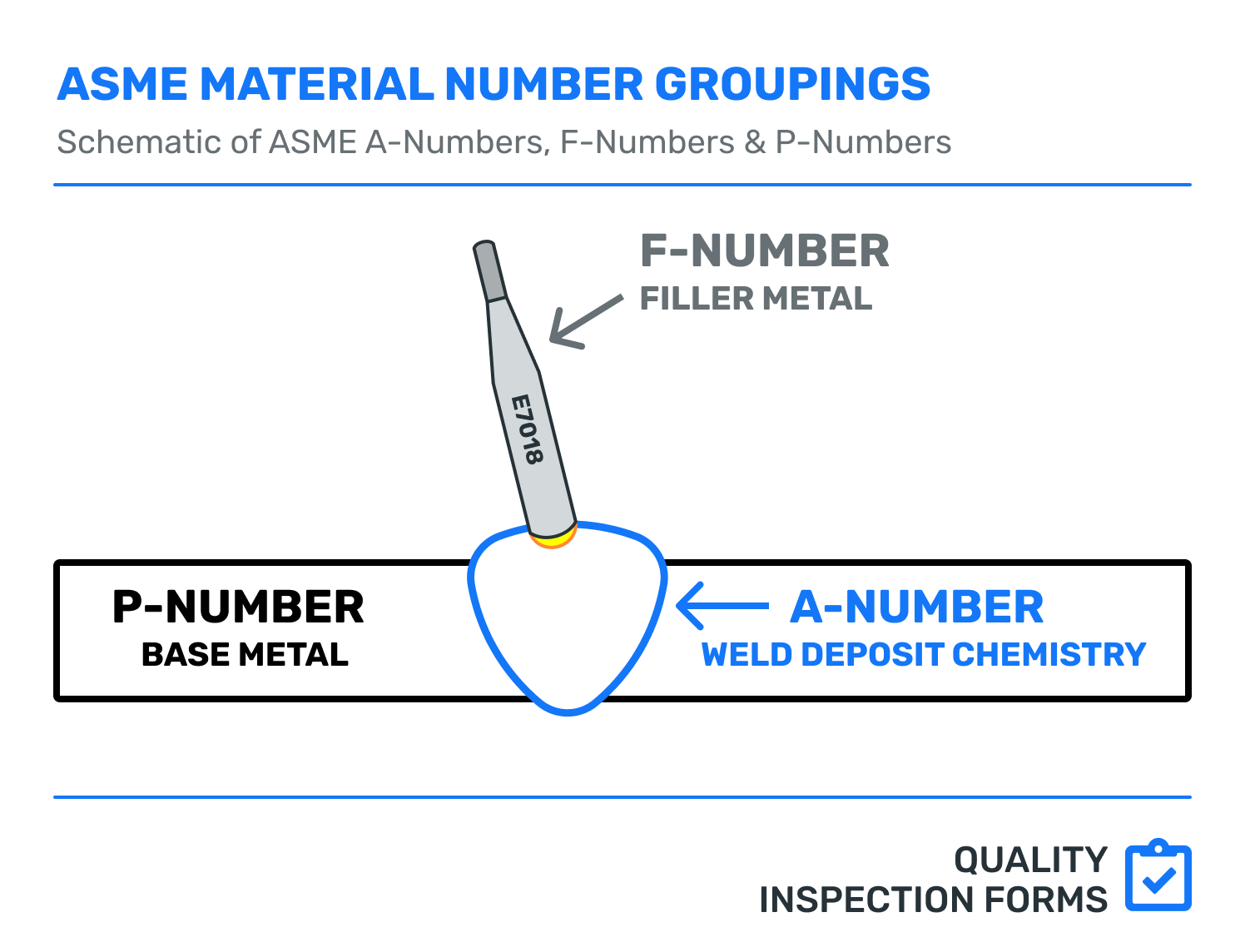

P-NUMBER and F-NUMBER and A-NUMBER

P-Number : Base Metal

F-Number : Filler Metal

A-Number : Weld metal in the “as-welded” state

BASE METAL GROUPINGS

Code bodies have different jurisdictions and applications that exist in response to industry, product application, and geographies. A general example of this would be that ASME primarily covers pressure boundary welding, and AWS covers structural applications.

As a result of these differences a variety of material groupings, and naming conventions have been created.

Table demonstrating the different Base Material Grouping Names

Some base materials (Specification & Type) may be common between the different code standards, and others will not be. Some carbon steels like structural I-Beam listed in D1.1 will not be listed in ASME. It is also the case that common carbon steel pipe listed in ASME will not be listed in AWS standards. This can be confusing at times as both material shapes are considered to be carbon steel, but understanding the jurisdictional application helps to resolve the confusion.

BASE METAL ALLOY GROUPINGS

P-Numbers have been laid out as chronological numeric segments which are assigned to different alloy groups as detailed in the following ASME P-Number Alloy Groupings from Section IX QW-420.

| P-Number Range | Alloy Group |

|---|---|

| P-1 thru P-15F | Steel Alloys |

| P-21 thru P-26 | Aluminum Alloys |

| P-31 thru P-35 | Copper Alloys |

| P-41 thru P-49 | Nickel Alloys |

| P-51 thru P-53 | Titanium Alloys |

| P-61 thru P-62 | Zirconium Alloys |

P-NUMBER LIST

The following is a comprehensive list of P-Numbers, their general material description, and some typical material specification examples.

P-Number Table

| P-Number | General Description | Typical Material Specification Within This P-Number Group |

|---|---|---|

| 1 | Carbon Steel | SA-36, SA-106 Gr. B, SA-350 Gr. LF1, SA-516 Gr. 70 |

| 3 | 1/2 Cr & 1/2 Mo Steels | SA-209 T1, SA-213 T2, SA-234 WP1, SA-335 P1 & P2 |

| 4 | 1-1/4 Cr-Mo Steels | SA-182 F11 CL. 1, SA-213 T11, SA-335 P11 |

| 5A | 2-1/4 Cr-Mo Steels up to 75 ksi | SA-182 F22 CL. 1, SA-213 T22, SA-335 P22 |

| 5B | 5 to 9 Cr-Mo Steels up to 85 ksi | SA-182 F5 & F9, SA-213 T5 & T9, SA-234 WP5 & WP9 |

| 5C | 2-1/4 to 9 Cr-Mo Steels over 85 ksi | SA-182 F3V, SA-336 F3V, SA-508 3V, SA-541 3V |

| 6 | Stainless Steel - Martensitic | SA-216 TP410 & TP429, SA-182 F6B, F6NM & F429, A473 410 |

| 7 | Stainless Steel - Ferritic | SA-240 TYPE 405, 409, & 410S, SA-240 TYPE 430 |

| 8 | Stainless Steel - Austenitic | SA-182 F304L, SA-182 F316L, SA-240 TYPE 304L & 316L |

| 9A | 2% Ni Steel | SA-182 FR, SA-234 WPR, SA-333 GR. 9, SA-350 LF9 |

| 9B | 3% Ni Steel | SA-333 3, SA-350 LF3, Cl. 2 |

| 9C | 4.5% Ni Steel | SA-352 LC4 |

| 10A | Low Alloy Steel | SA-225 C & D, SA-487 GR. 1, Cl. A & B |

| 10B | Low Alloy Steel | SA-213 T17 |

| 10C | Low Alloy Steel | SA-612 UNS K02900 |

| 10H | Stainless Steel - Duplex | SA-240 S31803, S32205 & S32750, SA-789 S32205 |

| 10I | Stainless Steel - High Cr | SA-182 FXM-27CB, SA-240 S44635, SA-336 FXM-27CB |

| 10J | Stainless Steel - High Cr & Mo | SA-240 S44700, SA-268 S44735, SA-479 S44700 |

| 10K | Stainless Steel - High Cr, Mo & Ni | SA-240 S44700, SA-268 S44735, SA-479 S44700 |

| 11A | HSLA (High Strength Low Alloy) | SA-333 8, SA-420 WPL8, SA-533 TYPE A, Cl. 3 |

| 11B | HSLA (High Strength Low Alloy) | SA-517 A, E, F, & B, SA-592 F |

| 11C | Age Hardening Alloy Steel Forgings | A859 TYPE A, Cl. 1 |

| 15E | 9% Cr, Creep strength enhanced | SA-182 F92, SA-213 T91 & T92, SA-335 P91 & P92 |

| 21 | Aluminum - 1000 & 3000 series | SB-209 A95050, SB-221 A91100, SB-234 A91060 |

| 22 | Aluminum - 5000 series | SB-209 A95052, SB-221 A95454, SB-234 A95052 |

| 23 | Aluminum - 6000 series | SB-209 A96061, SB-221 A96061, SB-221 A96063 |

| 25 | Aluminum - 5000 series | SB-209 A95456, SB-221 A95456, SB-241 A95086 |

| 26 | Aluminum Castings | SB-26 A24430 & A03560 |

| 31 | Copper | SB-111 C10200, SB-152 C10400, SB-187 C10200 |

| 32 | Brass | SB-111 C28000, SB-135 C23000, SB-283 C46400 |

| 33 | Cu-Si Alloys | SB-198 C65500, SB-283 C65500 |

| 34 | Cu-Ni Alloys | SB-111 C70400, SB-359 C70600, SB-466 C71500 |

| 35 | Aluminum Bronze Alloys | SB-111 C60800, SB-148 C95500, SB-150 C61400 |

| 41 | Nickel Alloys | SB-160 N02200, SB-161 N02200, SB-162 N02200 |

| 42 | Ni-Cu Alloys | UNS N04400, N04405 (MONELS) |

| 43 | Ni-Cr-Fe Alloys | UNS N06600, N06625, N10276 (INCONELS & HASTELLOYS) |

| 44 | Ni-Mo & Ni-Mo-Cr Alloys | UNS N06022, N10629, N10665, N10675 (HASTELLOYS] |

| 45 | Ni-Cr- Fe & Ni-Fe-Cr-Mo-Cu Alloys | UNS N08020, N08800, N08810, N08825 (INCOLOYS) |

| 46 | Ni-Cr-Si Alloys | UNS N06045, N08330, N12160 |

| 49 | Ni-Cr-Co-Mo-Fe-W Alloys | SB-815 UNS R31233, SB-818 UNS R31233 |

| 51 | Titanium Alloy 35-58 ksi | UNS R50250, R50400, R52400, R52404 |

| 52 | Titanium Alloy 65-70 ksi | UNS R50550, R53400 |

| 53 | Titanium Alloy 90 ksi | UNS R56320, R56323 |

| 61 | Zirconium 55 ksi | SB-523 TYPE R60702 - ALL PRODUCT FORMS UNS R60702 |

| 62 | Zirconium 70-80 ksi | SB-523 TYPE R60705 - ALL PRODUCT FORMS UNS R60705 |

S-NUMBER

In 2009, S-Numbers were removed from Section IX. S-Numbers were assigned to materials that were acceptable for use by the ASME B31 Code or had been deemed acceptable by Code Cases within the Boiler and Pressure Vessel Code, but which were not included in ASME Section II. They are no longer used, and base metals previously assigned S-Numbers have now been assigned P-Numbers and Group Numbers. So P-Numbers are now the single system used.

GROUP NUMBER

Ferrous base metals have been assigned Group Numbers, which create subsets of P-Numbers. Group numbers are primarily required when WPS’s are required to be qualified by impact testing or in other words when supplementary essential variables apply to the welding procedure.

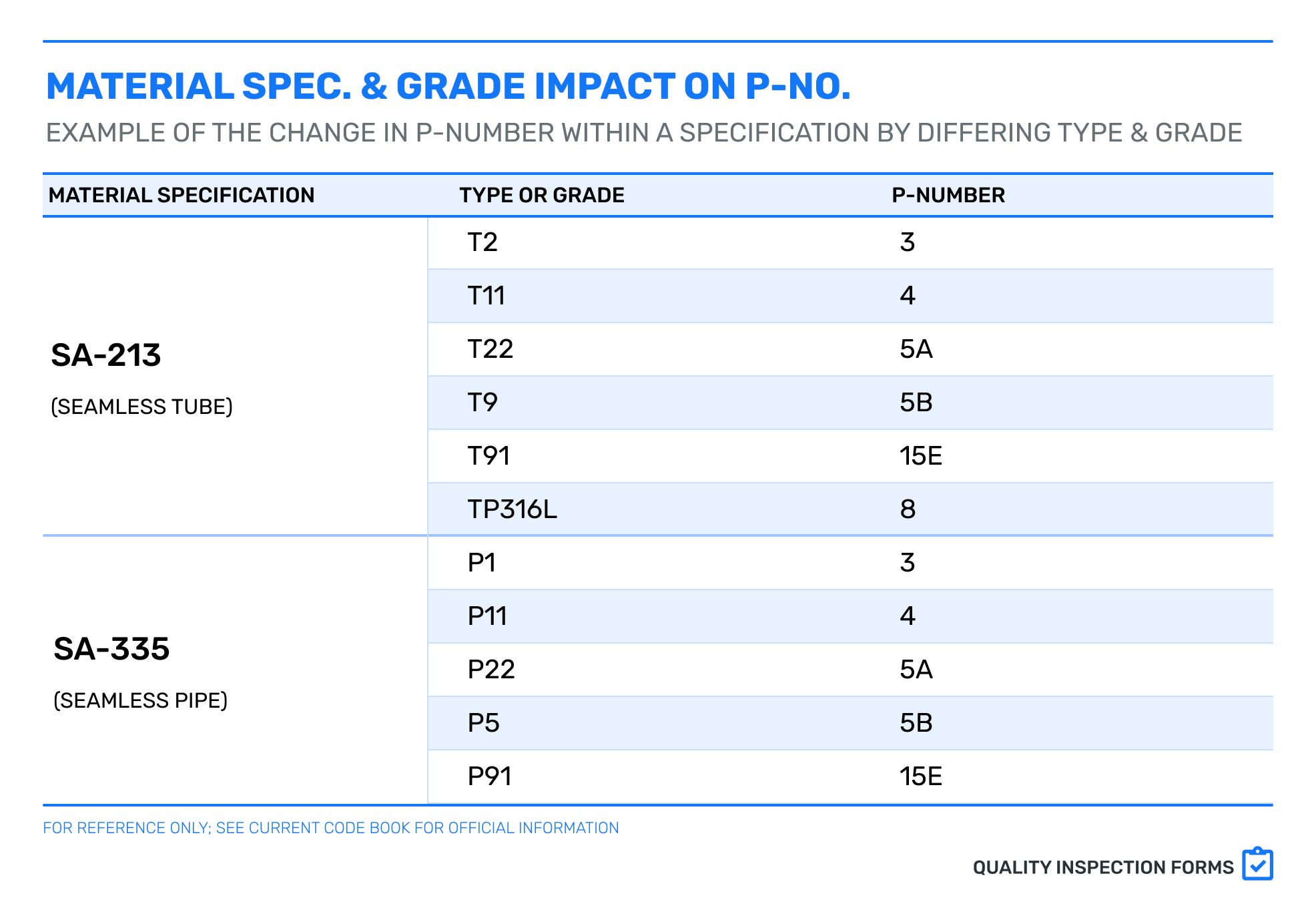

SPECIFICATION, TYPE OR GRADE

Both the materials specification and the Type or Grade are essential information in having the correct material. The material specification essentially calls out the product form. The Type or Grade of that specification is more aligned to the metallurgy of that product form and heavily influences the P-Number as well as the Group Number of the material.

There are some material specifications that are almost exclusively one P-Number, such as SA-240 & SA-312, where almost all of the materials in those specifications are P-No. 8. This can sometimes lead to the incorrect assumption that the specification alone is a sufficient amount of information to determine a material’s P-Number.

The following table provides examples of materials where Type or Grade can change the P-Number of the material.

ASME P-Number Spec and Grade

The following is an example of how Type or Grade can change the Group Number within a single material specification.

ASME P-Number Spec and Grade

FERROUS & NON-FERROUS MATERIALS

In general, ferrous metals contain iron; non-ferrous metals, on the other hand, do not contain iron. ASTM and ASME have created a prefix convention for identifying ferrous and non-ferrous materials.

A/SA is used to define those materials which are ferrous.

B/SB is used to define those materials which are non-ferrous.