ER70S-6 A-Number 1 Chemistry

ER70S-6 is one of the most popular solid wire filler metals for GMAW and GTAW yet depending on the chemistry of each lot, it may not comply with the ASME A-No. 1 chemistry limitations for Manganese and Silicon. It is important for those deploying ASME welding procedures with ER70S-6 filler metal listed as A-No. 1 to have procurement quality controls in place to monitor the Manganese and Silicon values on the filler metal MTR.

Does ER70S-6 Comply with ASME A-No. 1?

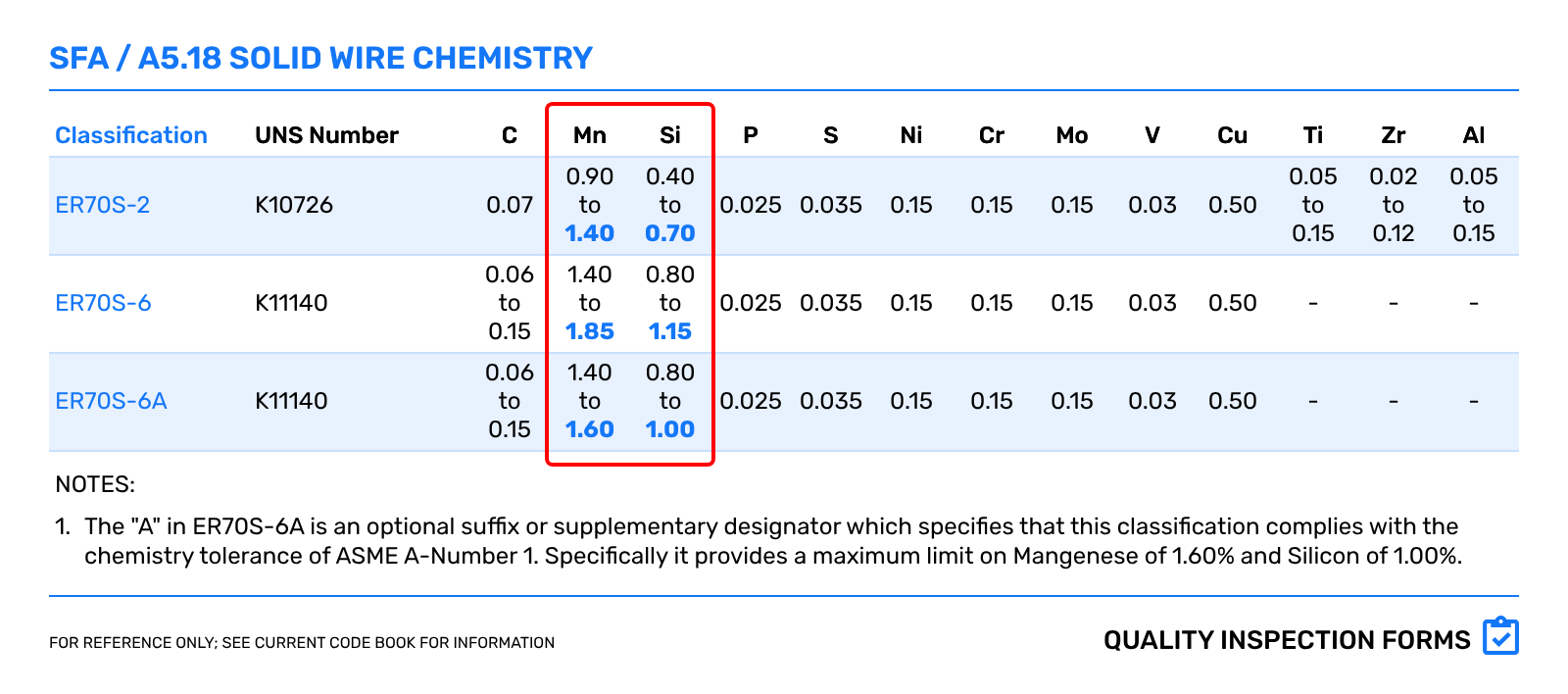

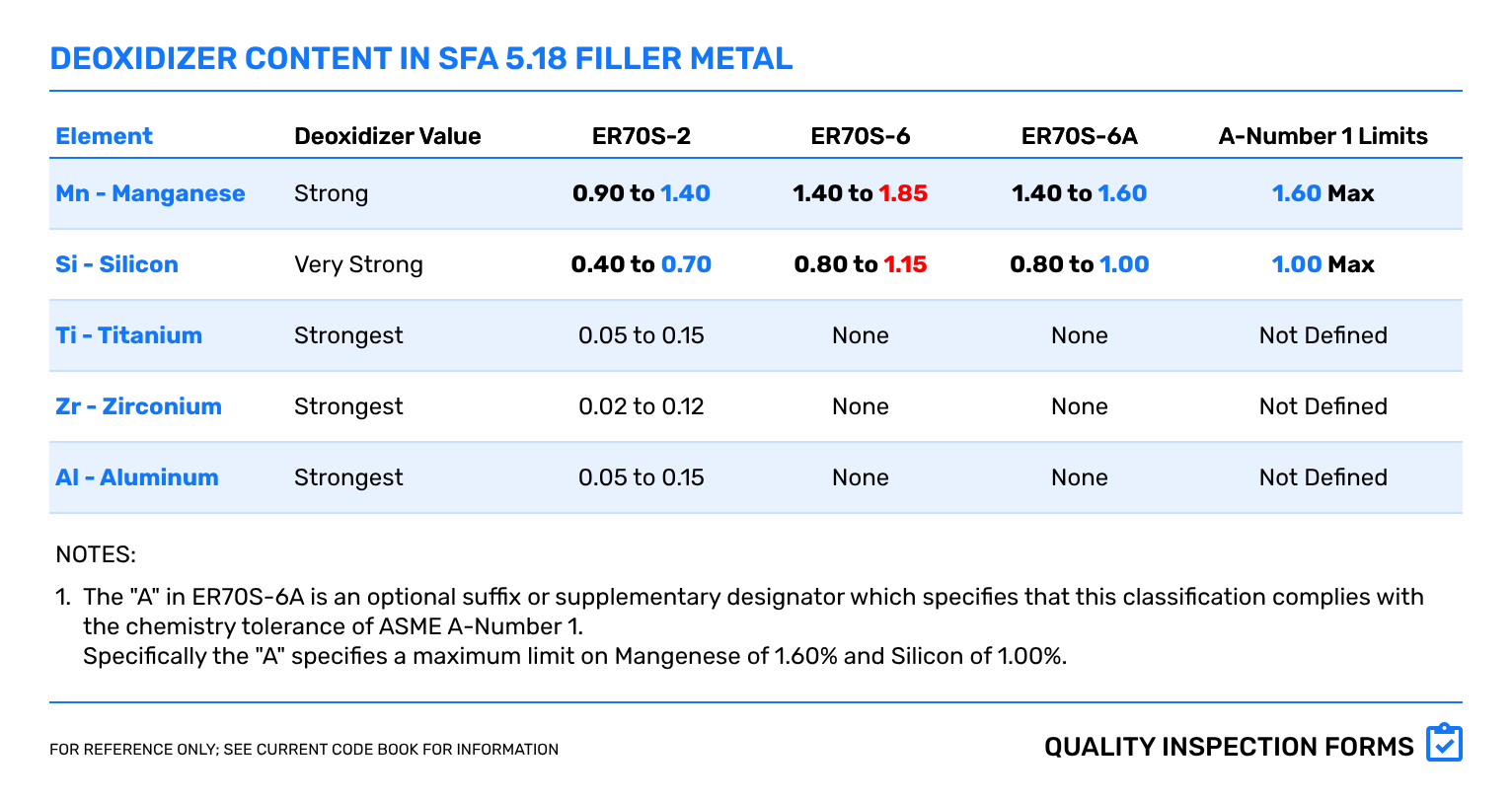

The ER70S-6 classification chemistry allows for a maximum of 1.85% Manganese and 1.15% Silicon while ASME has placed a limit of 1.60% Manganese and 1.00% for Silicon. Manufacturers of filler metal often produce the filler metal with Manganese and Silicon low enough to comply with the A-No. 1 requirement, but validation of the MTR is key to remaining in compliance with the welding procedure and ASME Section IX code requirements.

A limitation to relying on the filler metal MTR is in the fact that most filler metal MTR’s are only a “Typical MTR” or a “Certificate of Compliance” which is a representative sample of multiple large lots of product, and what you have may or may not have the same exact chemistry.

Refer to the following articles that expand on filler metal MTR’s:

Can I Use ER70S-6 and Still Claim A-No. 1 on the WPS?

The most common way to address ER70S-6 A-No. 1 compliance is to place a note on the WPS specifying that the filler metal MTR is to be checked for a maximum of 1.60% Mn and 1.00% Si before use. If this solution is implemented it must also be supported with a program that actually checks before the ER70S-6 is used, or you may find yourself in a difficult jam when it is discovered that the filler metal being used is out of compliance after the fact.

Another option to be in compliance with A-No. 1 would be to specify ER70S-6A which is a classification that properly controls the chemistry to be in conformance with A-No. 1 specified limits.

Pros and Cons of Not Claiming A-No. 1 on the WPS?

Option 1: Do not list the A-No. 1 for ER70S-6 on the PQR or WPS

Pro: MTR monitoring for chemistry compliance is not required for the PQR or any production welding performed under the WPS. The control is simply the classification of the ER70S-6 filler metal and the tolerances permitted by the 5.18 specification.

Con: Some customers may require A-No. 1 chemistry for use on their products. This method also prevents the flexibility of changing the classification within the grouping of those that comply with A-No. 1 chemistry, as A-Number is an essential variable as defined by ASME Section IX.

Option 2: Control the filler metal used on the PQR and claim A-No. 1, but don’t specify A-No. 1 on the WPS

Pro: This allows for reduced effort, where only the filler metal of the PQR is controlled, but the filler metal in production does not have to be monitored for Mn & Si max limit compliance. This makes for a more robust and flexible PQR in the case that specifying A-no. 1 would be required in the future.

Con: Some customers may require A-No. 1 chemistry for use on their products.

Option 3: Control the filler metal used on the PQR and the WPS claiming A-No. 1, and check all MTR’s

Pro: Both PQR and WPS are compliant to ASME A-No. 1 and no customers or auditors are likely to reject the WPS based on this detail.

Con: This requires a lot of effort and would be included in internal and/or external auditing to confirm the program is maintaining compliance. If an error is found it may cause a lot of unnecessary problems.

Reference ASME Section IX QW-404.5 for different options on how to handle ER70S-6 on the PQR and WPS.

What is ER70S-6A?

To address the the possible A-No. 1 mismatch ASME has developed an ER70S-6A classification. Where the “A” is a supplemental designator indicating compliance to the ASME A-No. 1 chemistry.

“A” ASME A-No. 1

“A” is an optional designator of the 5.18 Classification used for “S-6” or ER70S-6 classification, which indicates that the rod meets the additional manganese and silicon max limits for ASME A-No. 1.

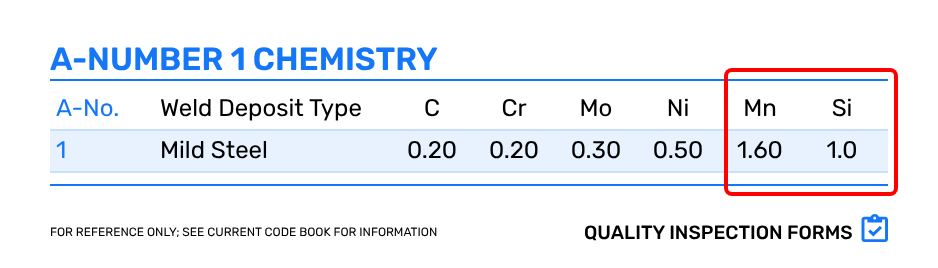

A-No. 1 limits require a maximum of manganese limit of 1.60%, and a maximum silicon limit of 1.0%

So a filler metal rod labeled as ER70S-6A indicates conformance to ASME A-No. 1 and can be used on PQR’s and WPS’s in lieu of notes specifying limitations of manganese and silicon.

A comparison of the SFA 5.18 chemistry table to the ASME Section IX A-Number table quickly exposes the fact that ER70S-6 can fall outside the maximum allowable for Manganese and Silicon.

Here is a comparison of deoxidizer content between ER70S-2 and ER70S-6. ER70S-2 has a tradition of being used on the root for piping, which has largely been eroded by the more recent popularity of ER70S-6, largely based on ER70S-6 being less expensive per weight.