NACE MR0103 : Sulfide Stress Cracking Resistant Materials

Metallic Materials Resistant to Sulfide Stress Cracking in Corrosive Petroleum Refining Environments

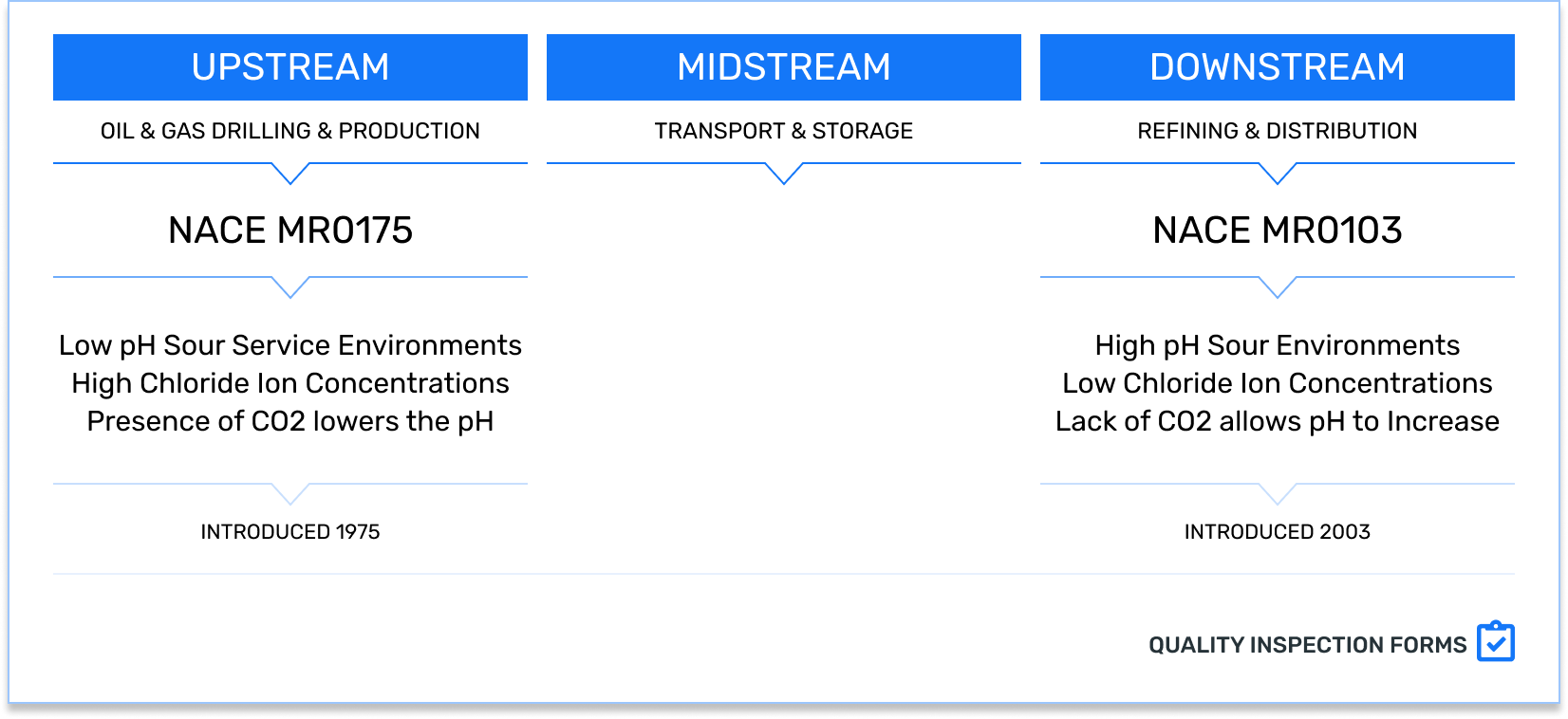

NACE MR0103 was developed as a downstream refinery specific standard for sour service metallic materials in 2003 (the 03 in MR0103).

This standard is often confused with NACE MR0175 which applies to only oil and gas production, or upstream activities was introduced in 1975 (the 75 in MR0175) as they have a lot of similarities.

MR0103 establishes material requirements for resistance to SSC in sour services containing H2S in either a gas or wet aqueous phase. If the requirements of MR0103 and NACE SP0472 are complied with issues due to Sulfide Stress Cracking (SSC) can be eliminated.

A primary factor in Sulfide Stress Cracking (SSC) is tensile strength as indicated by hardness. Testing a material for its tensile strength is a destructive test, and can be used for qualifying welding procedures, but in production that is not practical. Hardness has a strong enough correlation to tensile strength that it can be used in nondestructive testing to determine a materials susceptibility to SSC. As a result hardness testing is specified as the primary testing requirement for many materials associated with cracking environmental service.

MR0103 incorporates the relevant knowledge in materials, material property requirements and heat treatments, gained from the extensive experience of MR0175.

Terms and Definitions

ASCC: Alkaline Stress Corrosion Cracking

HAZ: Heat Affected Zone

HBW: Brinell Hardness

H = hardness, B = Brinell, W = Tungsten, the material of the indenter

HIC: Hydrogen Induced Cracking

H2S: Wet Hydrogen Sulfide (Sour Service), a colorless, flammable, and toxic gas with a strong odor of rotten eggs

HSC: Hydrogen Stress Cracking

SOHIC: Stress Oriented Hydrogen Induced Cracking

Sour Service: where process fluids contain sufficient levels of hydrogen sulfide (H₂S), a highly corrosive, flammable, and toxic gas that can lead to cracking, embrittlement, or failure of metallic materials. This condition is distinguished from "sweet service," which involves low or no H₂S content.

SSC: Sulfide Stress Cracking, cracking of a metal under the combined action of tensile stress and corrosion in the presence of water and H2S. SSC is a form of hydrogen stress cracking

Max Hardness Tables from MR0103

| Table | Clause | Description |

|---|---|---|

| 1 | 12 | Material Groups Road Map per ISO 17945 |

| 2 | 13 | Max Hardness Requirements for P-Numbered Alloy Steels |

| 3 | 13 | Chemical Composition Requirements for Austenitic Stainless Steels |

| 4 | 13 | Max Hardness Requirements for Precipitation Hardenable Stainless Steels |

| 5 | 14 | Max Hardness Requirements for Cold-Worked Nickel-Chromium-Molybdenum Alloys |

| 6 | 14 | Max Hardness Requirements for Precipitation Hardenable Nickel Alloys |

| 7 | 14 | UNS R30035 Heat Treatments |

| 8 | 14 | Max Hardness Requirements for Titanium Alloys |

| 9 | 16 | Common Bolting Materials Meeting the Requirements of Clause 13 and Clause 14 |

Table of Contents of MR0103

List items highlighted in blue have information listed below

Clause 1: Scope

Clause 2: Normative References

Clause 3: Term and Definitions

Clause 4: Symbols and Abbreviations

Clause 5: Responsibilities

Clause 6: Factors contributing to SSC

Clause 7: Materials

Clause 8: Hardness Requirements

Clause 9: Procedure for Adding New Materials

Clause 10: New Restrictions and Deleted Materials

Clause 11: Qualification of Unlisted Alloys

Clause 12: Standard Road Map

Clause 13: Ferrous Materials

Clause 14: Non-ferrous Materials

Clause 15: Fabrication Requirements

Clause 16: Bolting

Clause 17: Plating, Coatings, and Diffusion Process

Clause 18: Special Components

Clause 19: Valves

Clause 20: Compressors and Pumps

Annex A: Sulfide Species Plot

Annex B: Background Information on Hardness Testing and Requirements

Annex C: Welding Procedure Qualification Hardness Survey Layouts

Contributing Factors to SSC - Clause 6

The general factors contributing to Sulfide Stress Corrosion are as follows

Chemical composition

Strength as indicated by Hardness

Heat treatment

Microstructure of the material exposed to the sour environment

Total tensile stress present in the material (Load + Residual)

Exposure to environment: H2S concentration, pH, aqueous phase presence, bisulfide ion concentration, and free cyanides

Temperature

Duration of exposure

Hardness Requirements - Clause 8

Hardness testing where a maximum hardness is specified is a primary requirement for materials susceptible to Sulfide Stress Cracking (SSC)

Different hardness testing methods can be used

Brinell or Comparison Hardness Testing - Nondestructive testing, the method for production

Vickers and Rockwell - Destructive testing, typically used on procedure qualification

ASTM Standards for the different Hardness Methods

Rockwell: ASTM E18 or ISO 6508-1

Brinell: ASTM E10 or ISO 6506-1

Comparison Hardness Testing: ASTM A833

Vickers: ASTM E384 (replaced ASTM E92) or ISO 6507-1

Hardness Conversion Table: use ASTM E140 or ISO 18265

Establishing the actual hardness of a material requires an average of a sufficient number of hardness tests

Individual hardness readings exceeding the specified value shall be considered acceptable if the average of several reading taken within close proximity does not exceed the specified values of the average and/or the maximum value established by the applicable code.

MR0103 does not permit the use of portable hardness testing methods to verify compliance, unless explicitly approved by the end user or owner.

Ferrous Material Requirements - Clause 13

Carbon Steels listed as P-No. 1 Group 1 or 2 need to be supplied as one of the heat treat conditions listed in MR0103 paragraph 13.1.1 (c)

P-No. 1 weldments shall be produced using one or more of the methods outlined in “NACE SP0472: Methods and Controls to Prevent In-Service Environmental Cracking of Carbon Steel Weldments in Corrosive Petroleum Refining Environments” to prevent excessive hardness

MR0103 only states the hardness requirement for P-1 for after PWHT and for piping materials formed by heating (see table below)

MR0103 references the hardness requirements of NACE SP0472 for P-1 welds in production, and PQR requirements for weld deposits and the Heat Affected Zone (HAZ) (see table below)

MR0103 summarizes the Brinell hardness for other ASME P-No. materials in Clause 13 Table 2 referenced below, but also includes detailed information that should be reviewed from the standard when dealing with any of these materials

Max Hardness Values from NACE MR0103, NACE SP0472, and ISO 17495

| Alloy Type | ASME P-No. | Max Hardness | Reference |

|---|---|---|---|

| Carbon Steel | P-No. 1 - Weld Deposit Production | 200 HBW | MR0103 13.1.2.2, 13.1.7, & NACE SP0472 2.2.1 |

| Carbon Steel | P-No. 1 - After PWHT | 200 HBW | MR0103 13.1.6.2 |

| Carbon Steel PQR | P-No. 1 - Weld Deposit (PQR) Single Reading | 248 HV10 | NACE SP0472 2.3.5.3.6 |

| Carbon Steel PQR | P-No. 1 - Weld Deposit (PQR) Avg. Reading | 210 HV10 | NACE SP0472 2.3.5.3.6 |

| Carbon Steel PQR | P-No. 1 - HAZ (PQR) | 248 HV10 | NACE SP0472 2.3.5.3.5 & Table 1 |

| Carbon Steel | P-No. 1 - Piping formed by Heating | 225 HBW | MR0103 13.1.2.3 |

| Carbon Steel | P-No. 1 - Cold worked pipe or fittings | 190 HBW | MR0103 13.1.6.3 |

| "Other" Carbon Steels | "Other" Carbon Steels | 237 HBW | MR0103 13.1.3 |

| Chrome PQR | P-No. 3, 4, or 5A PQR Single or Avg. Reading | 248 HV10 | MR0103 13.1.8 |

| 1/2 Cr & 1/2 Mo | P-No. 3 | 225 HBW | MR0103 Table 2 |

| 1-1/4 Cr | P-No. 4 | 225 HBW | MR0103 Table 2 |

| 2-1/4 Cr | P-No. 5A | 235 HBW | MR0103 Table 2 |

| 5 Cr | P-No. 5B | 235 HBW | MR0103 Table 2 |

| 9 Cr | P-No. 5C | 235 HBW | MR0103 Table 2 |

| Martensitic Stainless | P-No. 6 | 235 HBW | MR0103 Table 2 |

| Ferritic Stainless | P-No. 7 | 235 HBW | MR0103 Table 2 |

| Steel Alloy | P-No. 10A | 225 HBW | MR0103 Table 2 |

| Steel Alloy | P-No. 10B | 225 HBW | MR0103 Table 2 |

| Steel Alloy | P-No. 10C | 225 HBW | MR0103 Table 2 |

| Steel Alloy | P-No. 10F | 225 HBW | MR0103 Table 2 |

| High Strength Low Alloy (HSLA) | P-No. 11 | 225 HBW | MR0103 Table 2 |

Non-Ferrous Material Requirements - Clause 14

Hardness requirements are defined for Nickel, Titanium, Aluminum, and Copper alloys

Fabrication Requirements - Clause 15

General fabrication requirements

Corrosion resistant overlays, hard facing overlays, and cladding

15.3 : Welding

15.3.4 : Vickers hardness testing survey layouts are detailed in Annex C

Cladding on carbon steels, alloy steels, and martensitic stainless steels

Identification stamping