FILLET WELD GAUGE

FUNCTION AND USE OF THE BASIC FILLET WELD GAUGE

FILLET WELD GAUGES

A fillet weld gauge is used to measure the leg length and throat thickness of a fillet weld. The basic fillet weld inspection tool has a coped and scalloped feature on the ends of the rectangular tool for measuring convex and concave fillet welds.

Basic Fillet Weld Gauge

HOW TO MEASURE FILLET WELDS

Select the desired fillet weld gauge size

Measure leg length using the coped end, check each toe.

Measure the throat thickness using the scalloped end, confirm that the throat of the weld touches the face of the gauge

How to Measure a Fillet Weld

MEASURING CONVEX FILLET WELDS

The coped portion of a fillet weld gauge is used to measure the leg length of fillet welds. The coped portion is elongated on the bottom portion to keep it from interfering with the bottom edge toe of the fillet weld, with the upper portion being sized for accurate measurements. This requires that the gauge be positioned twice, once for each leg of the fillet weld.

MEASURING CONCAVE FILLET WELDS

The scalloped portion is used to measure the throat of the weld. The center portion of this side has a short flat feature positioned at 45° degrees, which is designed to come in contact with the weld face. When the flat on the throat side has contact, it is confirmed that the fillet weld meets or exceeds the throat dimension specified on the inspection tool.

CALCULATING FILLET WELD THROAT FROM LEG LENGTH

Fillet Weld Throat and Leg Length

CONVEX FILLET WELD

Convex fillet welds have an exterior surface that curves or bumps outward, similar in shape to that of the exterior portion of a circle.

The throat of the weld should not exceed the required reinforcement or throat thickness maximums.

The following diagram provides all of the standard terminology associated with a convex fillet weld.

Fillet Weld Terms for a Convex Fillet Weld

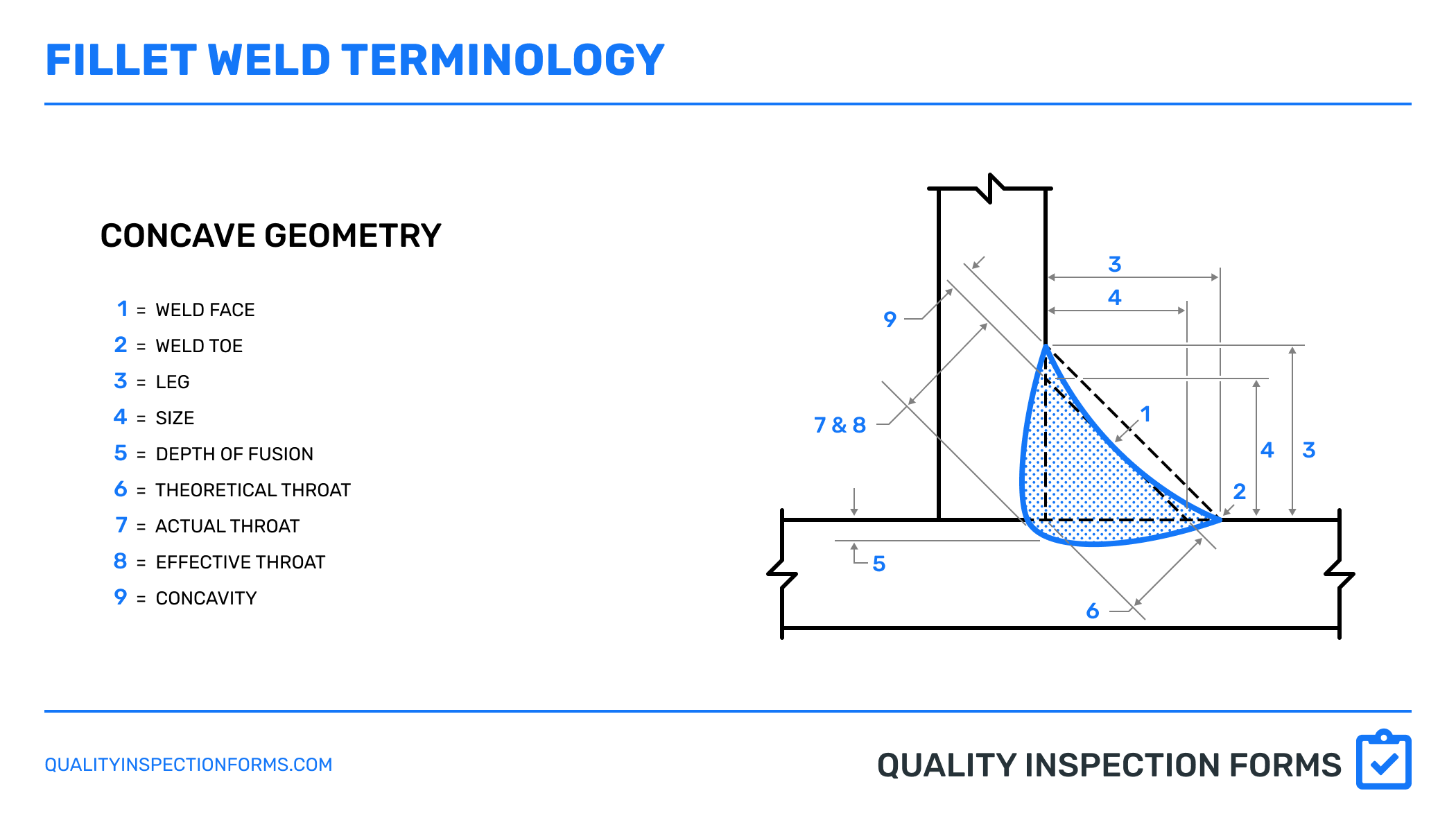

CONCAVE FILLET WELD

Concave fillet welds have an exterior surface that curves or dips inward, similar in shape to that of the interior portion of a circle.

The throat of the weld should not be less than the required reinforcement or throat thickness minimums.

The following diagram provides all of the standard terminology associated with a concave fillet weld.

Fillet Weld Terms for a Concave Fillet Weld