PIPE SCHEDULE AND SIZE CHART

PIPE DIMENSIONS PER ASME B36.10M

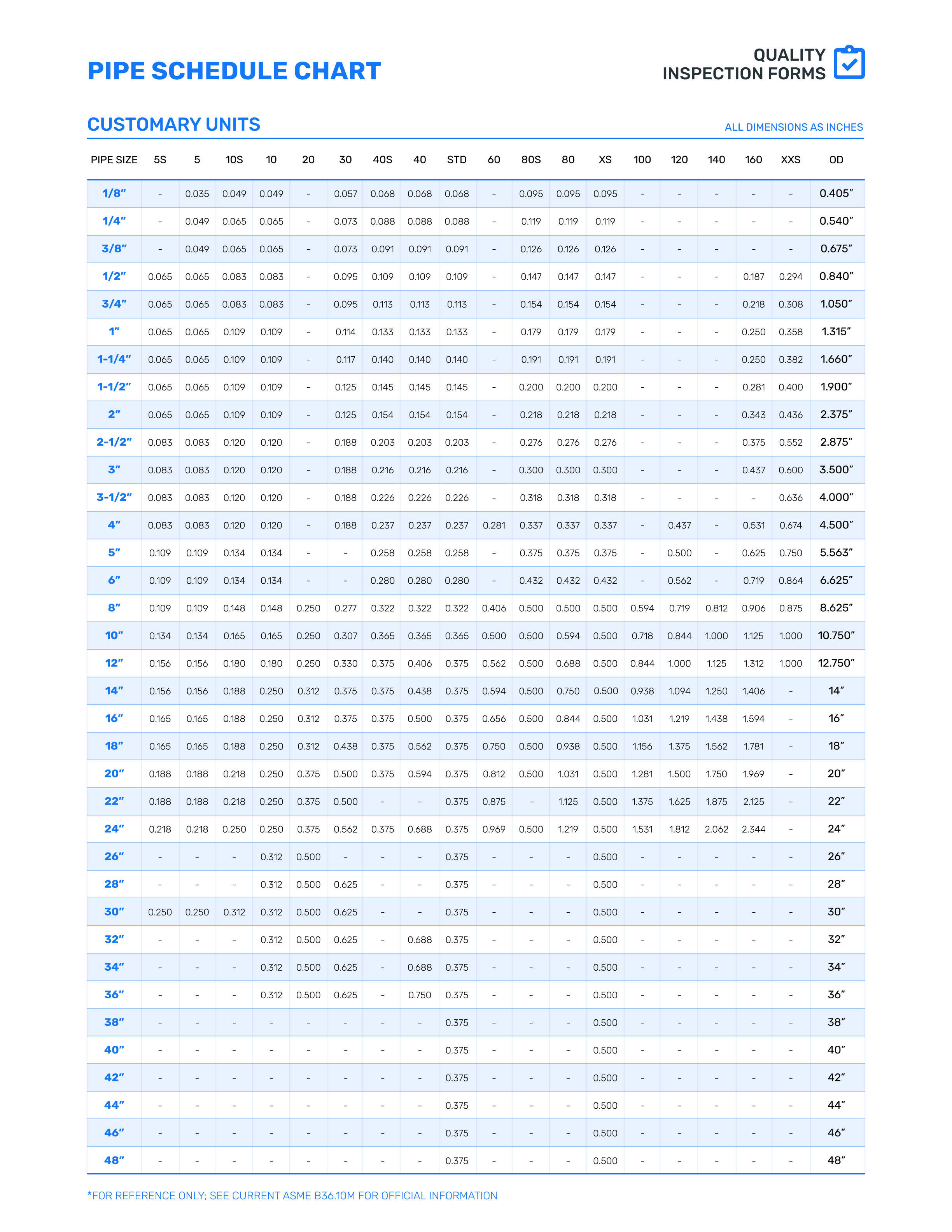

A pipe schedule and size chart provides the shared values of thickness and diameter. Pipe Schedule is a term used to describe the thickness of the pipe. Pipe size or NPS is a dimensionless designator used in the US customary or standard system, which references the piping’s diameter. NPS is an acronym standing for Nominal Pipe Size. DN is the SI or metric designation, which is an acronym for diameter nominal.

Nominal is a term used with some building material dimensional descriptions such as building lumber, and piping. Nominal is defined as: a quantity or dimension stated or expressed but not necessarily corresponding precisely to the real value.

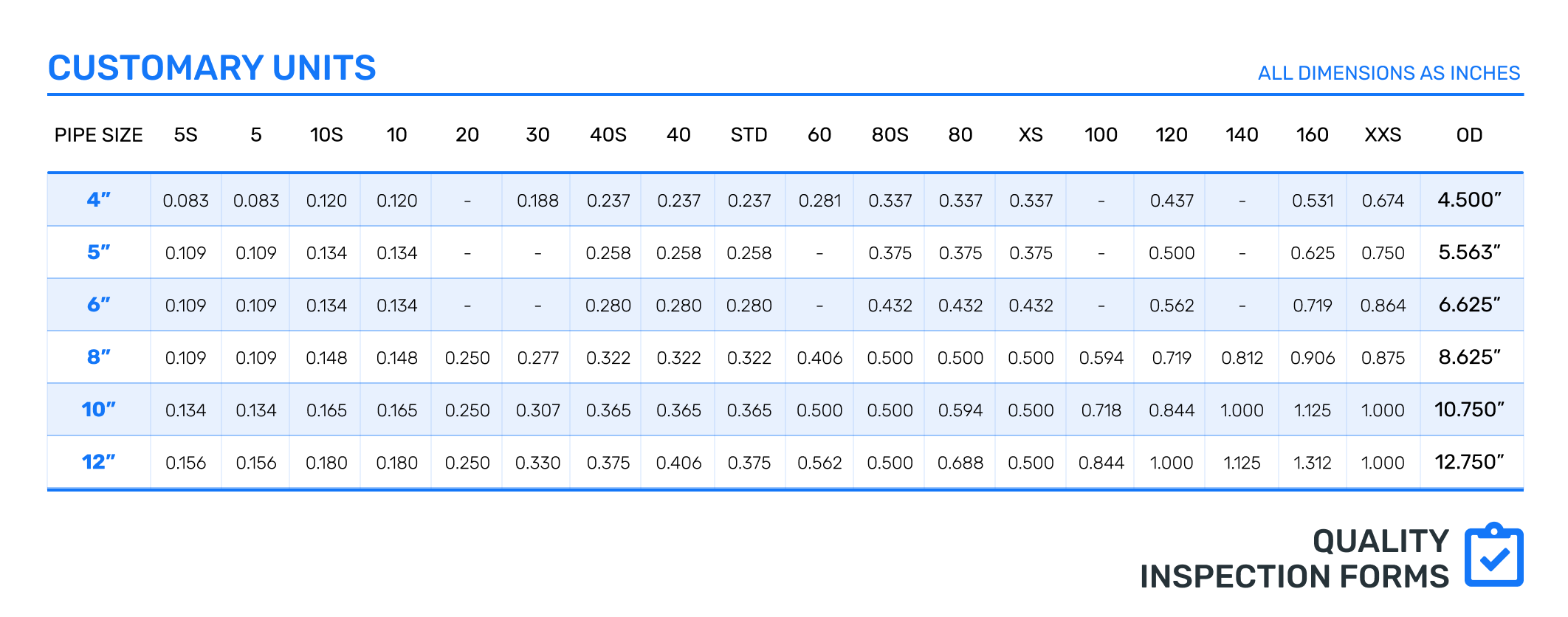

Piping in the bill of materials (BOM) on drawings specifies the NPS and schedule. When the NPS and schedule are known, the thickness can be determined. This is done by finding the thickness value at the intersection of the NPS and Schedule values provided.

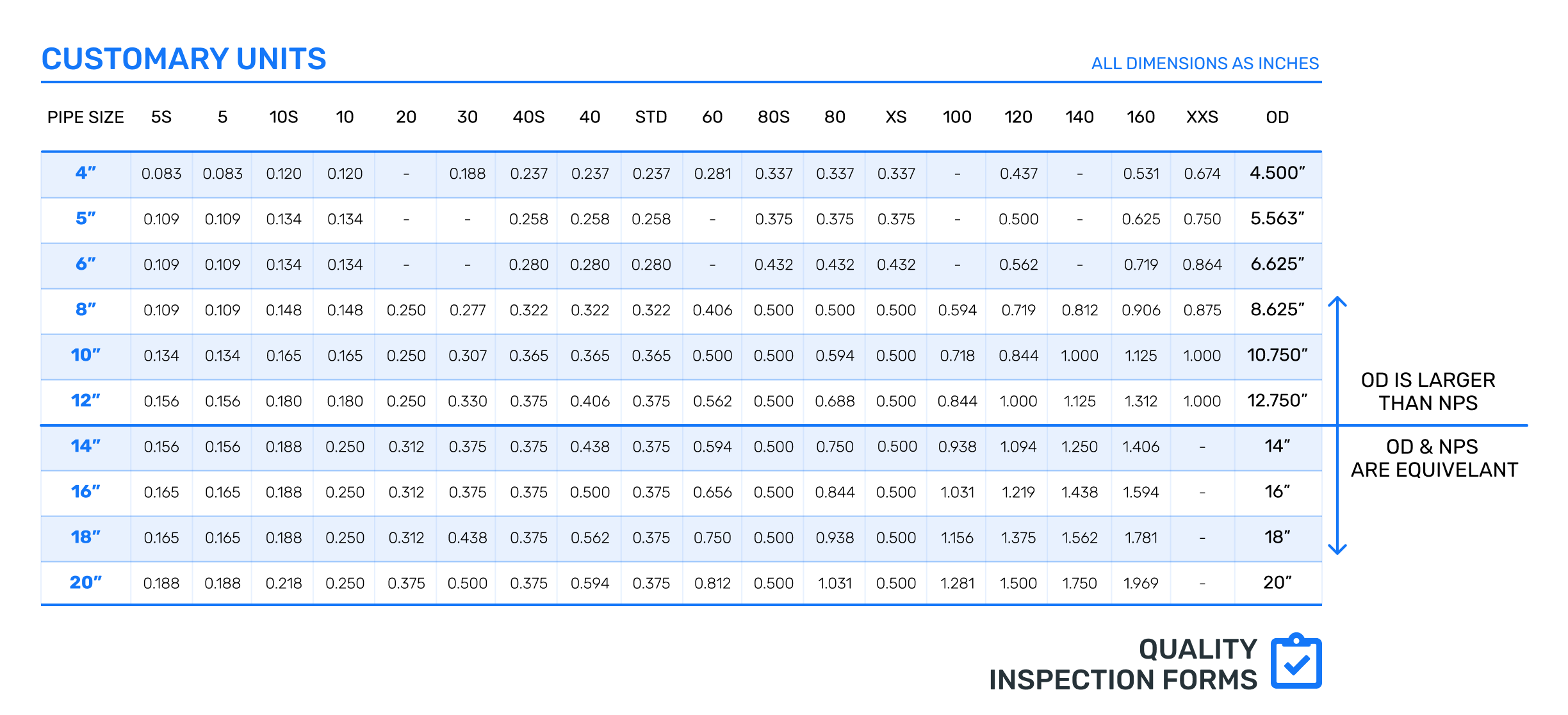

For each row, the NPS or Pipe Size value corresponds to one OD or Outside Diameter size in the chart. Each pipe schedule value in the listed columns share the same NPS and corresponding OD or outside diameter dimension. As a result, the ID or Inside Diameter does change as the wall thickness gets thinner or thicker.

PIPE & TUBE

Pipe applies to tubular products of dimensions commonly used for pipeline or piping systems. The nominal diameter (NPS) and outside diameter (OD) of NPS 12 (DN 300) and smaller have outside diameters numerically larger than their corresponding nominal sizes. The nominal diameter (NPS) and outside diameter (OD) of NPS 14 and above are equivalent.

So for piping NPS 12 and smaller, the nominal diameter and OD do not match. For piping, NPS 14 and larger nominal diameter and outside diameter do match. In contrast, the outside diameters of tubes are numerically identical to the sizing number value along the entire sizing scale.

Break point where pipe outside diameter and the nominal size are the same

Pipe is the most common product form in the ASME B31 piping codes. Tubing is the most common product for use in the construction of boilers covered by ASME Section I and Section IV jurisdiction.

MATERIAL AVAILABILITY

The most common piping schedule is schedule 40. Schedules 5, 60, 100, 120, and 140 are rarely used. Material availability should be considered when specifying materials, as uncommon schedules may be difficult to obtain.

SCHEDULE DESIGNATIONS

The wall thickness designations Standard (Std.), Extra-Strong (XS), and Double Extra-Strong (XXS) have been commercially used designations for many years. The Schedule Numbers were subsequently added as a convenient designation for use in ordering pipes. Either designation is acceptable when specifying pipe.

PIPE SCHEDULE & SIZE CHART

Download your copy of a Pipe Schedule & Size Chart created in conformance with ASME B36.10M.