ASME B31.3 Pressure Testing

Pressure testing involves subjecting a completed piping system to a controlled pressure test—either hydrostatic (using liquid, typically water) or pneumatic (using gas, typically air or nitrogen)—to verify its strength, leak-tightness, and ability to withstand design pressures. The test confirms that the system, including all components like pipes, fittings, and welds, meet the safety and performance requirements specified in ASME B31.3.

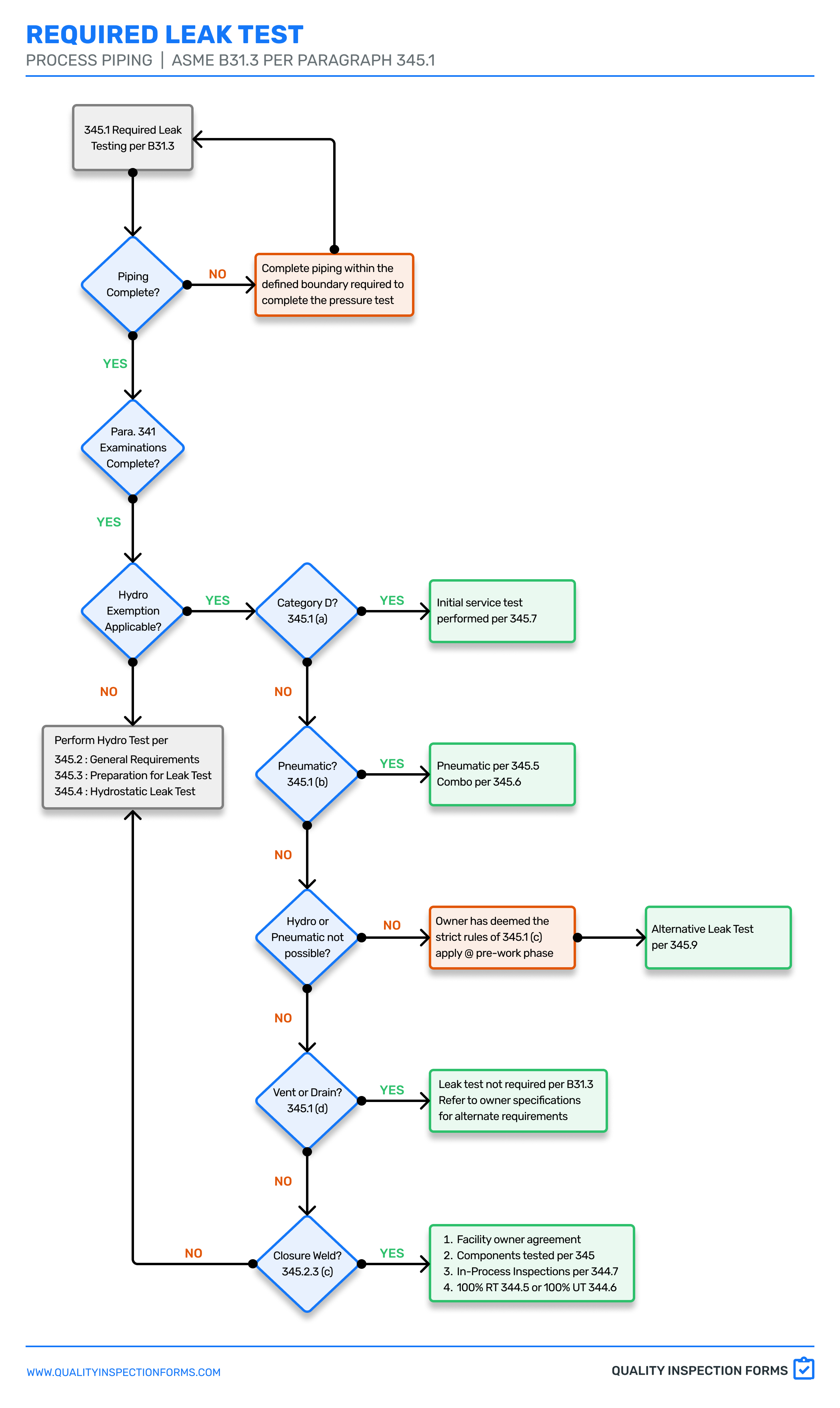

Pressure testing is performed only after the required non-destructive examinations required by paragraph 341 are complete.

The code indicates preference for hydrostatic pressure testing as it is safer than pneumatic testing. Pneumatic pressure testing can be performed when hydrotesting is not feasible, but safeguards have to be put in place to minimize the hazards associated with the stored potential energy of compressed gas. Refer to ASME B31.3 345.5 for pneumatic testing details and 345.4 for hydrostatic testing details.

Where does ASME B31.3 Address Pressure Testing?

Paragraph 345.1 Required Leak Test

Paragraph 345.2 General Requirements for Leak Tests

Paragraph 345.3 Preparation for Leak Test

Paragraph 345.4 Hydrostatic Leak Test

Paragraph 345.5 Pneumatic Leak Test

Paragraph 345.6 Hydrostatic - Pneumatic Leak Test (Combined)

Paragraph 345.7 Initial Service Leak Test

Paragraph 345.8 Sensitive Leak Test

Paragraph 345.9 Alternative Leak Test

What Has to be Put on the Pressure Test Record?

B31.3 paragraph 345.2.7 addresses the requirements of pressure test records.

The most basic fields that shall be included on the pressure testing record include the following:

Date of test

ID of piping system tested

Test fluid

Test pressure

Certification of results by examiner (fabricator, manufacturer, or contractor)

What other Fields are Commonly Found on a Pressure Test Record?

Project Name, Project Number, Owner, PO Number, Water Purity, Test Duration, Required Pressure, Measured Pressure, Test Medium, Pressure Gauge ID, Calibration Date, Ambient Temperature, Comments, Witness Names and Signatures.

Other descriptive fields like those above should be captured on the pressure test record and be appropriate for the Owner requirements, the industry, and the quality program of the company you work for.

Pressure testing records shall be made of each piping system properly pressure tested and included in turnover documentation by the Examiner (fabricator, manufacturer, or contractor).

If the Inspector (Owner) certifies the pressure testing by their own record and then retains that documentation provided by the Examiner (fabricator, manufacturer, or contractor) is not required to be retained, see B31.3 345.2.7.

Also refer to general records requirements including retention of records in B31.3 346.2 and 346.3

Are there Exemptions to Hydrostatic Pressure Testing?

There are some conditions that permit an exemption to the required hydrostatic pressure testing.

Service Tests : Piping defined by the owner or owner’s engineer to be Category D fluid service can be “service tested”. This means that as the piping is placed into service there is an initial service leak test using the fluid service of the pipe. Refer to ASME B31.3 paragraph 345.7 for details on Initial Service Leak Testing.

Pneumatic Test : Pneumatic testing can be performed in lieu of hydrostatic pressure testing for piping systems where the owner has defined hydro testing to be unfeasible. The primary reasons for pneumatic testing would be due to the service fluid being incompatible with water, or design conditions such as the fluid service is a gas, and the structural supports for the system are not able to support the water weight during hydrostatic testing. There are safety considerations regarding the hazards of the stored energy of compressed gas, consult ASME PCC-2 Appendix 501 for details on industry best practices regarding pneumatic testing. Refer to ASME B31.3 paragraph 345.5 for pneumatic testing, and B31.3 paragraph 345.6 for combo hydrostatic pneumatic testing.

Alternative Leak Test : There are some very limited cases where the owner may define both hydrostatic and pneumatic testing impracticable. Those cases have to meet all the requirements of ASME B31.3 paragraph 345.1 (c) and be performed in accordance with B31.3 paragraph 345.9 “Alternative Leak Test”

Vents and Drains : Downstream of the last shutoff valve the portions of piping systems that are open to the atmosphere such as for vents and drains need not be leak tested. Refer to B31.3 paragraph 345.1 (d).

Closure Welds : A closure weld can be exempted from pressure testing if the conditions of B31.3 345.2.3 (c) are satisfied, refer to this B31.3 Closure Welds article for more details.

How long does a pressure test have to last?

The test pressure shall be maintained for a minimum of 10 minutes per B31.3 345.2.2 (a) per code.

Owners may require a longer pressure test, so make sure to check contract specifications.

Is the full pressure required for the duration of the visual examination for leaks?

As long as the minimum test duration at full pressure has been met the pressure can be reduced to no less than the design pressure to allow for personnel to inspect in a safer environment if high pressures are a concern. Refer to B31.3 345.2.2 (a).

What are the requirements for pressure test gauges?

One or more test gages are required for the test per B31.3 345.2.2 (d)(1)

If using dial indicator gages, the target pressure should land in the middle of the range of the gage per B31.3 345.2.2 (d)(2)

If using digital pressure gages a wider range of capacity can be used than that specified for dial indicating gages. Consult with the manufacturers ranges for recommended use. Refer to B31.3 345.2.2 (d)(3)

If accuracy or resolution of the gages needs to be better than that of industry standards the engineering design should specify those requirements. Refer to B31.3 345.2.2 (d)(4)

Calibration of gages shall be performed utilizing a standard dead weight tester or a calibrated master gage.

Calibration shall be maximum of 12 months unless otherwise specified by the owner B31.3 345.2.2 (d)(5)

Is it Acceptable to Weld After Pressure Testing?

If repairs or additions are made after the leak test has been completed, that portion that has been affected needs to be retested. There are some exceptions to the requirement to retest, they are detailed in B31.3 345.2.6