16 Sections of a PQR

ASME Section IX PQR

What Is a PQR?

PQR is an abbreviation for Procedure Qualification Record. The PQR is a record of the welding variables which were used during the original qualification of the test coupon. The PQR also includes the destructive testing of that coupon which validates that acceptable mechanical properties were achieved as a result of the process parameters used. Once a PQR has passed the testing requirements it can then be used to write a WPS.

Refer to Section IX QG-102, and QW-200.2 for more details.

What is the Purpose of the PQR?

The purpose of the procedure qualification test is to establish and demonstrate that the proposed joining process is capable of producing the required mechanical properties for the intended application. The PQR is not intended to test the skill of the personnel running the PQR test, as that is the purpose of the welder performance test documented on a WPQ. Throughout Section IX and other welding codes it is important to keep “procedure” and “performance” requirements separated as they can and will have differing essential variables and objectives.

The PQR is a historical record that should not be actively revised except for the correction of typographical errors or rare occasions where the welding code adjusts variables applicable to the PQR. As a historical record the variables recorded on the PQR are the actual values or “actuals” of what was used to run the PQR coupon as compared to the WPS where ranges are listed based on the PQR.

Refer to Section IX QG-102, and QW-200.2 for more details.

What is Included on a PQR?

As a minimum, the PQR shall document the essential variables for the applicable process(es) used on the procedure qualification test, and the results of the required tests. When the PQR successfully passes the required testing it can then be used as the foundation to writing a WPS (Welding Procedure Specification).

When toughness testing is required for qualification of the procedure specification, the applicable supplementary essential variables shall be recorded for each process.

Refer to Section IX QG-102, and QW-200.2 for more details.

PQR Contents

The following is the table of contents for the PQR form QW-483 and the rest of this article.

PQR Header and General Section

QW-402 Joints

QW-403 Base Metals

QW-404 Filler Metals

QW-405 Position

QW-406 Preheat

QW-407 PWHT

QW-408 Gas

QW-409 Electrical Characteristics

QW-410 Technique

QW-150 Tensile Test

QW-160 Guided-Bend Tests

QW-170 Toughness Tests

QW-180 Fillet-Weld Tests

Other Tests

Certification and Signature

PQR Header General Section

Organization

Name of the qualifying organization

See QG-106.1 for organizational responsibilities

Companies can utilize PQR’s from companies acquired through mergers or acquisitions.

See QG-107 for handling use of PQR’s obtained through Ownership Transfers

PQR No.

Give the PQR a unique number or title

Keep the PQR number to a reasonable length

It is best practice if the PQR number includes information that reveals the contents of the PQR

Welding Process(es)

List the welding process or processes used on the PQR

It is common to have one or two weld processes on a single PQR, in some less common cases three or more may be used.

2 Process example: GTAW root and hot pass, FCAW for balance

3 Process example: GTAW root or 1st pass, FCAW for hot pass, and SAW for fill and cap

WPS No.

This connects the PQR to the WPS it is supporting

The WPS also has a field that refers to the PQR or PQR’s supporting the WPS

Type(s)

This refers to the welding process type, with the options being manual, semi-automatic, automatic, or machine

Date

This is the date of when the PQR was run or conducted

There is also a date on the bottom of the second page of the PQR for when the company representative certifies the PQR by their signature.

2. QW-402 Joints

Joint Design

State the joint design or joint type that was used for the PQR, other details included in other fields

Joint Configuration details

Root opening, Joint Angle, Face or Land, Misalignment (For groove welds)

Backing

It is important to detail the backing of each process used. Depending on how the form is set up place the weld process in the corresponding field of “Backing Yes” or “Backing No”

An open root process is recorded as Backing “No”

If Backing was used or a second process is involved on top of a first it is recorded as Backing “Yes”

Joint Sketch

Sketch the joint configuration with the bead sequence by weld layers

Record the deposition thickness of the filler metal(s) and record in QW-404

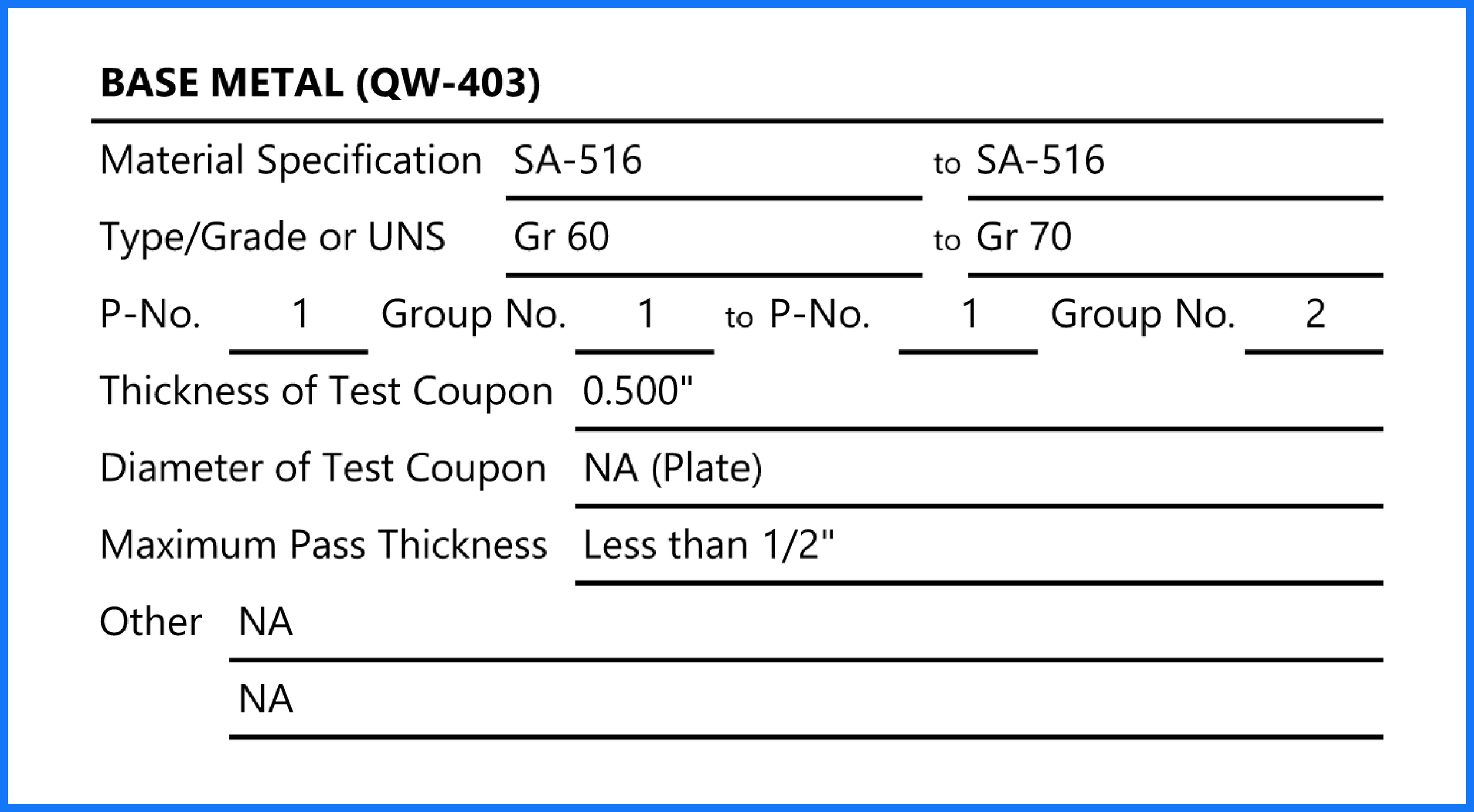

3. QW-403 Base Metals

Plate vs Pipe

QW-211 Qualification in plate also qualifies pipe and vice versa

Material Specification and Type

Record the material, by its specification and Type or Grade. This supports proper identification of the P-Number and Group Number.

Some materials may be best defined by their UNS Number (Unified Numbering System) so it is provided as an option

P-Number

Record the P-Number for the Base Metal used

Utilize Section IX Table QW-422 to determine the P-Number

Other resources would include

pnumbers.com searchable web page of P-Numbers

Blog article ASME P-Numbers

Group Number

Record the Group Number in addition to the P-Number

It is critical in toughness or supplementary testing applications that the Group Number is recorded

Thickness (Base Metal Thickness = “T” & Filler Metal Thickness = “t”)

The thickness of the PQR coupon needs to be recorded

The nominal material thickness is common practice, but a caliper measured thickness may also be used

Filler metal deposit thickness is recorded in QW-404 Filler Metals

Diameter

Diameter is used for piping materials

Max Pass Thickness

Section IX places restrictions on deposition thickness in excess of 1/2”, so it is important to document if the PQR is above or below that threshold

4. QW-404 Filler Metals

Specification

Include the specification from the filler metal used

Refer to Welding Filler Metal Specifications for more information

Classification

Include the classification from the filler metal used, include the full classification

Refer to Welding Filler Metal Classifications for more information

F-Number

Record the F-Number for the Filler Metal used

Utilize Section IX Table QW-432 to determine the F-Number

Other resources include

fnumbers.com searchable web page of filler metals and F-Numbers

Blog article ASME F-Numbers

A-Number

Record the A-Number for the Filler Metal used

Utilize Section IX Table QW-442 to determine the F-Number

Other resources include

fnumbers.com searchable web page of filler metals and A-Numbers

Blog article ASME A-Numbers

Filler Metal Product Form

Filler metal product forms are found in QW-404.23 and include

Bare (solid or metal cored)

Flux cored

Flux coated (solid or metal cored)

powder

Electrode Flux Classification

Applies to Submerged Arc Welding (SAW)

See QW404.35 regarding the flux wire classification used

Flux Type

Applies to Submerged Arc Welding (SAW)

See QW404.34 regarding Flux Type used

Flux Trade Name

Applies to Submerged Arc Welding (SAW)

Flux formulas are proprietary between manufacturers, so it is critical that this information be recorded

Weld Metal Thickness

Record the thickness of the weld filler metal deposited by each weld process involved

For applications such as E6010 & E7018, it is recommended to record each classification individually as the WPS needs to differentiate between the E6010 / F3 without backing, and the E7018 / F4 with backing.

Other

Used for random information related to the filler metal

When Submerged Arc Welding (SAW) is used, this field can be used for “Recrushed Slag”

See QW404.36 for requirements addressing if recrushed slag is used during qualification

5. QW-405 Positions

Position

Record the position of the PQR coupon as it was welded during qualification

See QW-120 for details on Test Positions for Groove welds

See QW-130 for details on Test Positions for Fillet welds

See QW-461.3 for test positions of Groove welds in Plate

See QW-461.4 for test positions of Groove welds in Pipe

Welding Progression

Record the progression used during the qualification

In some cases the root can be in a different direction from the balance so record each process individually if they are different

6. QW-406 Preheat

Preheat Temperature

Record the preheat temperature

Interpass Temperature

It is best practice to record the interpass temperature between each pass, and only record the max interpass temperature on the PQR

7. QW-407 PWHT

PWHT Temperature

Record the range of minimum and maximum temperatures of the PWHT during the holding time period

Holding Time

Record the holding time of the PWHT temperature representing the duration of the start to stop of the target temperature

Other

Use this space to include ramp rates, ramp thresholds, or other details related to the PWHT

8. QW-408 Gas

Record the gas type, mixture and flow rate for each applicable gas type listed in this section

Shielding Gas

Record the shielding gas individually for each applicable gas shielded weld process

Trailing Gas

When applicable trailing gas is applied in the trailing portion of the weld puddle protecting the weld from oxidation as it cools. This is normally only used in high alloy applications such as titanium.

Backing Gas

Backing gas is applied from the opposite side from where welding is taking place. Flow rate or in some cases oxygen purity is recorded for this variable.

9. QW-409 Electrical Characteristics

Current and Polarity

DCEP - Direct Current Electrode Positive (aka Reverse or Reverse Polarity)

DCEN - Direct Current Electrode Negative (aka Straight or Straight Polarity)

AC - Alternating Current

Amperage

Record the amperage for each pass, and record the min and max of the range

Voltage

Record the voltage for each pass, and record the min and max of the range

Pulsing

If pulsing is used record the details of the pulsing program. Pulsing is only a required variable for GTAW, but there are benefits for including it if used on the PQR to provide proper parameters for the WPS.

Wire Feed Speed

Record the WFS for each pass, and record the min and max of the range

Mode of Metal Transfer

This field only applies to GMAW/FCAW, see QW-409.32 for more information

Tungsten

Record the size and type of tungsten used during qualification. This is a Non-essential variable so adjustments to this variable can be made without re-qualification.

Heat Input

When supplementary testing is to be applied record the variables that are required for calculating the Heat Input

With some more modern equipment heat input can be determined through instantaneous energy or power, details and formulas are provided in Section IX QW-409.1

10. QW-410 Technique

Travel Speed

Record the travel speed for each pass, and record the min and max of the range

Stringer or Weave

Record if stringers, weaving, or both were used on the PQR. This variable can be influential in heat input applications.

Oscillation

Oscillation only applies to machine or automatic welding (weave applies to manual welding)

Single or Multi Pass

Identify if the PQR employed a single or multiple passes per side, see QW-410.9

Single or Multiple Electrodes

Identify if the PQR employed one or more than one electrodes. If more than one provide the specific amount

Back Gouge Method

11. QW-150 Tensile Test

QW-151 refers to Figures of Tension Tests see Figure QW-462.1(a) through Figure QW-462.1(e)

Reduced Sections for Tensile Tests

QW-151.1 Plate Reduced Sections

QW-151.2 Pipe Reduced Sections

QW151.3 Turned (round) Specimens

QW-152 Tension Test Procedure

QW-153 Tension Test Acceptance Criteria

12. QW-160 Guided-Bend Tests

QW-161 Specimens for Guided Bend Tests

Types of Guided Bend Tests

QW-161.1 Transverse Side Bends

QW-161.2 Transverse Face Bends

QW-161.3 Transverse Root Bends

QW-161.4 Subsize Transverse Face and Root Bends

QW-161.5 Longitudinal Bend Tests

QW-161.6 Longitudinal Face Bends

QW-161.7 Longitudinal Root Bends

QW-162 Guided Bend Test Procedure

QW-163 Acceptance Criteria for Bend Tests

13. QW-170 Toughness Tests

QW-170 Toughness Tests

QW-171 Charpy V-Notch Tests

QW-172 Drop Weight Toughness Tests

14. QW-180 Fillet-Weld Tests

QW-180 Fillet Weld Tests

QW-181 Procedure Qualification Specimens

15. Other Tests

For any other tests performed on the PQR coupon should be contained or referenced in this section

Some tests which have lengthy reports can be referenced by their report number, with the report then attached to the back of the PQR

Include what company performed the tests for the PQR

16. Certification and Signature

Include identifying information about the welder who performed the welding of the PQR

Keep Social Security Numbers off of the PQR

Include the typed name, as well as the signature of the organization’s certifying individual, typically the welding engineer or quality manager for the company. In the case of some smaller companies the manager or owner of the company may sign the PQR.

Refer to QW-201 for the Organizational Responsibility to certify the PQR