WPS QW-406 Preheat

ASME Section IX WPS : QW-406 Preheat Example

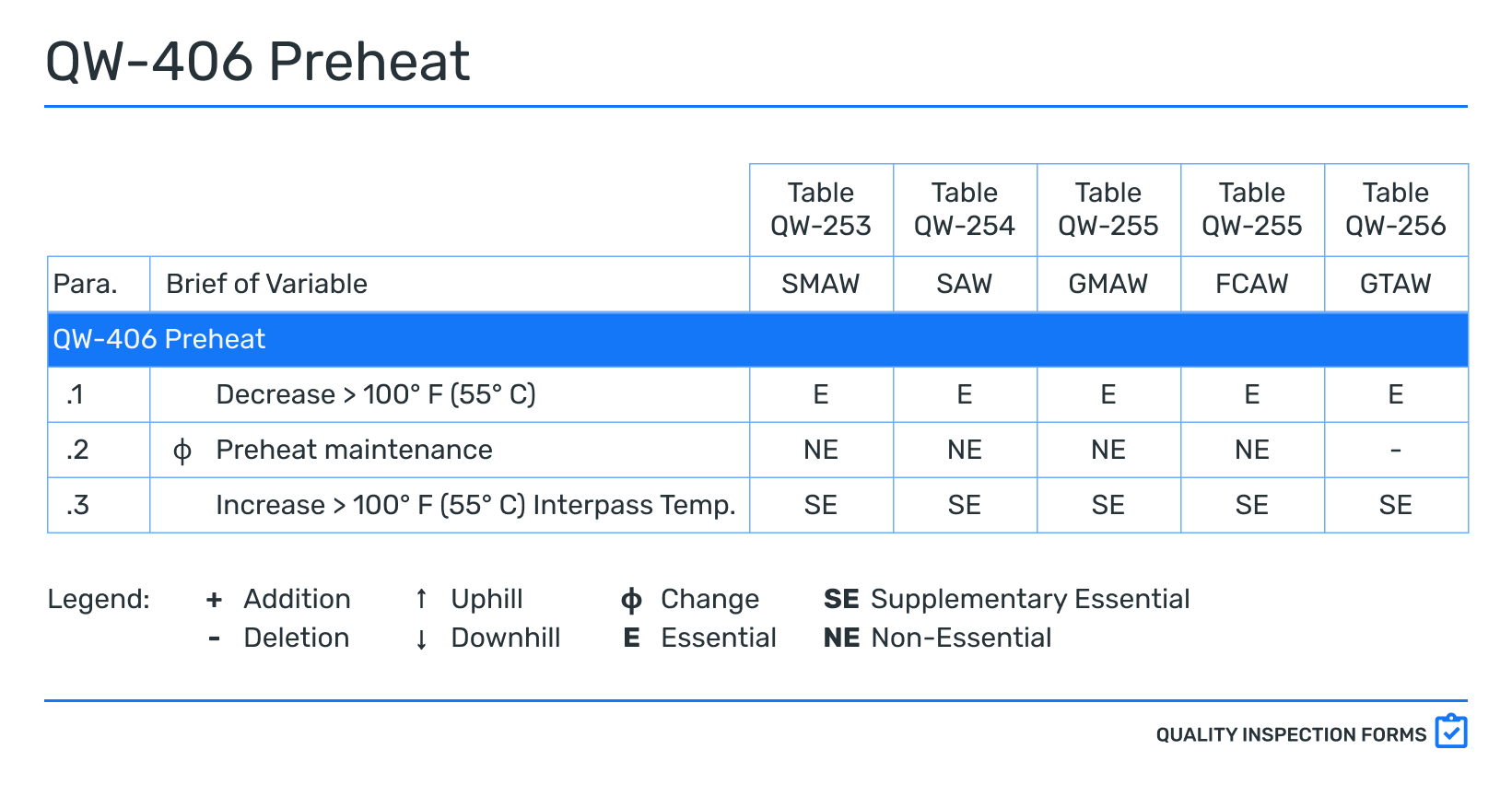

ASME Section IX Welding Variables for a WPS : QW-406 Preheat

QW-406.1 - Preheat Decrease

A decrease of more than 100°F or 55°C from that on the PQR

The minimum temperature for welding shall be specified on the WPS

QW-406.2 - Change in Preheat Maintenance

A change in the maintenance or reduction of preheat upon completion of welding

QW-406.3 - Preheat Increase

An increase of more than 100°F or 55°C from that on the PQR

There are three exceptions to this variable

Heat treatment above upper transformation temperature

WPS is for Austenitic or Duplex material with a solution heat treatment

The base metals are Austenitic Stainless Steel P-8, Aluminum Alloys P-21 thru 26, or Nickel Alloys P-41 thru 49

Essential Variable: Variables for which a change is considered to affect the mechanical properties (other than notch toughness) of the joint. Essential variable changes that fall outside their qualified range requires re-qualification.

Supplementary Essential Variable: Variables for which a change is considered to affect the toughness properties of the joint, heat-affected zone (HAZ), or base material.

Supplementary essential variables become additional essential variables in situations where toughness testing is required. When toughness testing is not required supplementary essential variables are not applicable.

Non-Essential Variable: Variables for which a change is considered to not affect the mechanical properties of the joint. This allows for editorial revisions to procedures within that permitted by Section IX without the need to requalify the procedure. Nonessential variables shall be documented on the procedure.