AWS D1.1 Fillet Welder Performance Test

AWS D1.1 Fillet Welder Testing

Tests to qualify welders are defined as “performance” tests in AWS D1.1, and the requirements are located in the following locations.

Plate Fillet Welder Testing : AWS D1.1 Part C of Clause 6 for flat structural shapes

Tubular Fillet Welder Testing : AWS D1.1 Part D of Clause 10 for tubular structural shapes

There are three fillet test configurations to qualify welders for fillet welds

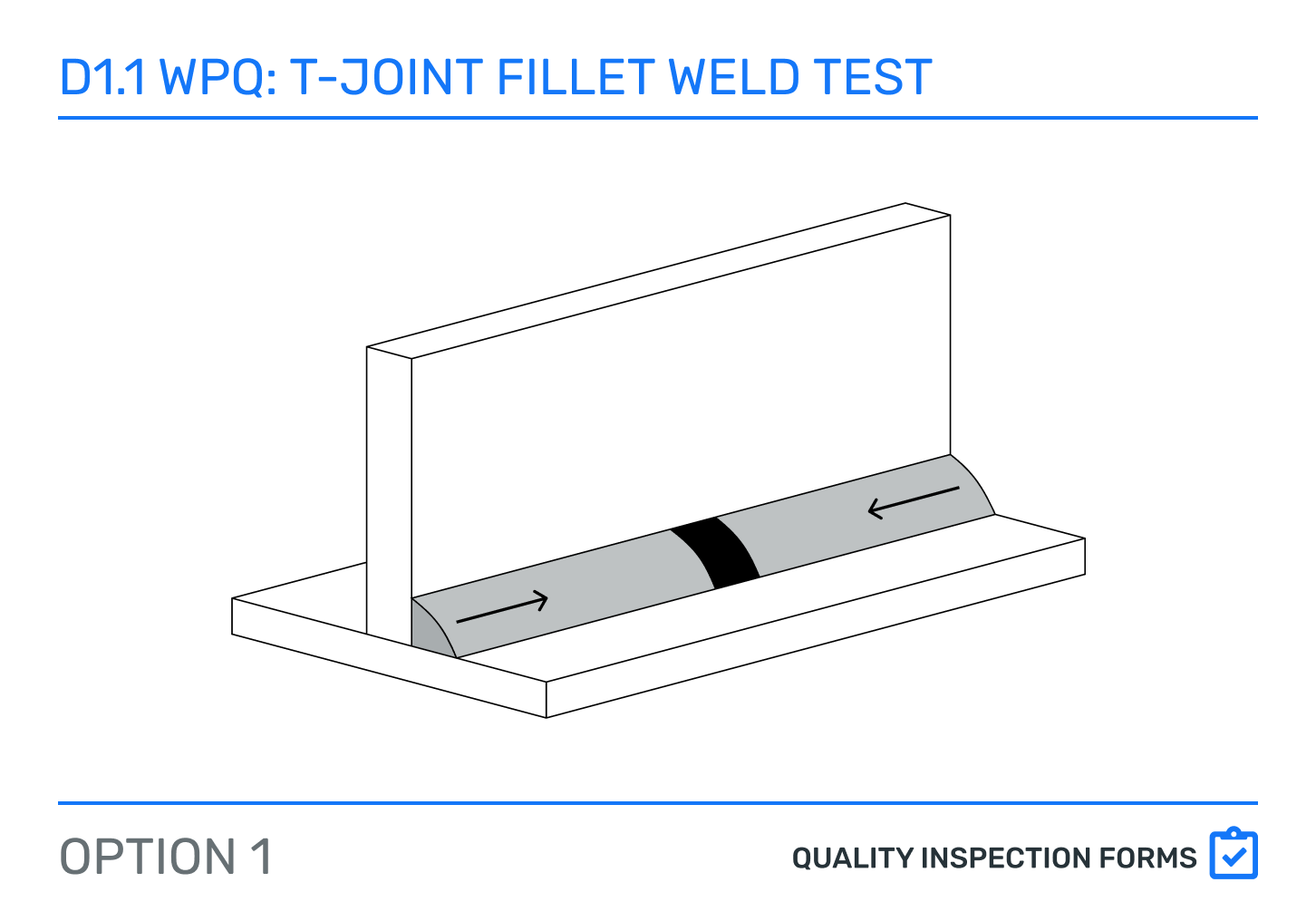

Option 1 : D1.1 Figure 6.25 - Plate (T-Joint style)

Option 2 : D1.1 Figure 6.22 - Plate (Butt joint style)

Option 3 : D1.1 Figure 10.16 - Tubular

Make sure to read the entirety of D1.1, to have the complete set of requirements for your application.

A welder performance qualification is the demonstration of a welder’s ability to produce welds meeting prescribed standards.

The acronym used by AWS for the documentation of a passed weld test is WPQR : Welder Performance Qualification Record. Colloquial names for the WPQR are paper, qual or qualification, cert or certification.

Can a Groove Test Qualify a Welder for Fillet Welds?

A successful Complete Joint Penetration (CJP) groove weld test also qualifies the welder to make fillet welds on plate (non-tubular); see AWS D1.1 6.22.2.

What should be considered for setting up the right fillet weld test?

Diameter > 24”: Will the application be for plate or greater than 24” diameter?

Then a plate test will work

Diameter < 24”: Will the application be for tubular products less than 24” in diameter?

Then a pipe to pipe or a pipe to plate test is necessary (see D1.1 para. 10.20 & Option 3 in Table 10.13)

Fillet Weld Size: What is the most common or largest weld size the welder will need to make?

make sure that the welder performs that largest size of fillet weld on the test as that is included as an essential variable on the test, this is specified as a note on the test assembly figures in D1.1.

Essential Variables: Review the other WPQ Essential Variables in D1.1 Paragraph 6.20 & Table 6.12

What do the Fillet Weld Tests Look Like?

Plate

Option 1 : D1.1 Figure 6.25 - T-Joint Style

Option 2 : D1.1 Figure 6.22 - Plate - Butt-Weld style where fillet welds are made to the backer, and the balance of the joint is then welded up, with a root bend to test the soundness of the weld.

Tubular

Option 3 : D1.1 Figure 10.16

(Figure 10.16 is a WPS Figure, that Table 10.13 invokes for use in tubular WPQ’s)

What inspection and testing is required for the completed D1.1 Fillet weld test?

Visual Inspection

See AWS D1.1 6.10.1 (the Performance Test uses the WPS requirements)

This is for the visual inspection of the finished weld

AWS D1.1 6.10.1.2 : Visual Inspection of Fillet Welds

Macroetch (Plate & Tubular : Option 1 or Option 3)

See AWS D1.1 6.23.2

Fillet weld macroetch preparation : see AWS D1.1 Figure 6.25

Macroetch Test Acceptance Criteria : see AWS D1.1 6.23.2.2

Fillet Weld Break Test (Plate : Option 1)

See AWS D1.1 6.23.4 for general requirements

Fillet Weld Test Coupon : see D1.1 Figure 6.25

Fillet Weld Break Acceptance Criteria : see D1.1 6.23.4.1

Root Bends (Plate : Option 2)

See AWS D1.1 6.10.3.1 (the Performance Test uses the WPS requirements)

Root : see AWS D1.1 Figure 6.22 for the test configuration & where to pull the root bend specimens from

See AWS 6.10.3.3 for the visual acceptance criteria for bend tests

See AWS Figure 6.22 shows that 2 root bends are required for each position performed in the test

Bend Test Jigs shall comply with one of the following : AWS D1.1 Figure 6.11, Figure 6.12, or Figure 6.13