AWS D1.1 Groove Welder Performance Test

Where can I find the code requirements for AWS D1.1 groove welder testing?

Tests to qualify welders are defined as “performance” tests in AWS D1.1

Plate Welder Testing : AWS D1.1 Part C of Clause 6 “Performance Qualification” for flat structural shapes

Tubular Welder Testing : AWS D1.1 Part D of Clause 10 “Performance Qualification” for tubular structural shapes

Make sure to read the entirety of Clause 6 Part C or Clause 10 Part D, to have the complete set of requirements for your application.

A welder performance qualification is the demonstration of a welder’s ability to produce welds meeting prescribed standards.

The acronym used by AWS for the documentation of a passed weld test is WPQR : Welder Performance Qualification Record. Other names for the WPQR are paper, qual or qualification, cert or certification. ASME uses the acronym WPQ for Welder Performance Qualification, so it is common to see that in use as well.

What should be considered for setting up the right weld test?

To determine the most effective test(s) you should consider what range of qualifications the welder needs to properly perform their daily welding tasks:

What range of positions are necessary for the welder to perform their work?

AWS D1.1 Table 6.10 : Positions qualified by Performance Plate Tests

AWS D1.1 Table 10.12 : Positions qualified by Performance Pipe and Box Tube Tests

What thickness range will the welder encounter?

AWS D1.1 Table 6.11 : Thickness and Diameter qualified by

AWS D1.1 Table 10.13 : Thickness and Diameter qualified by Pipe and Box Tube Tests

What welding process will the welder be using?

Run the weld test with the welding process to be used in production

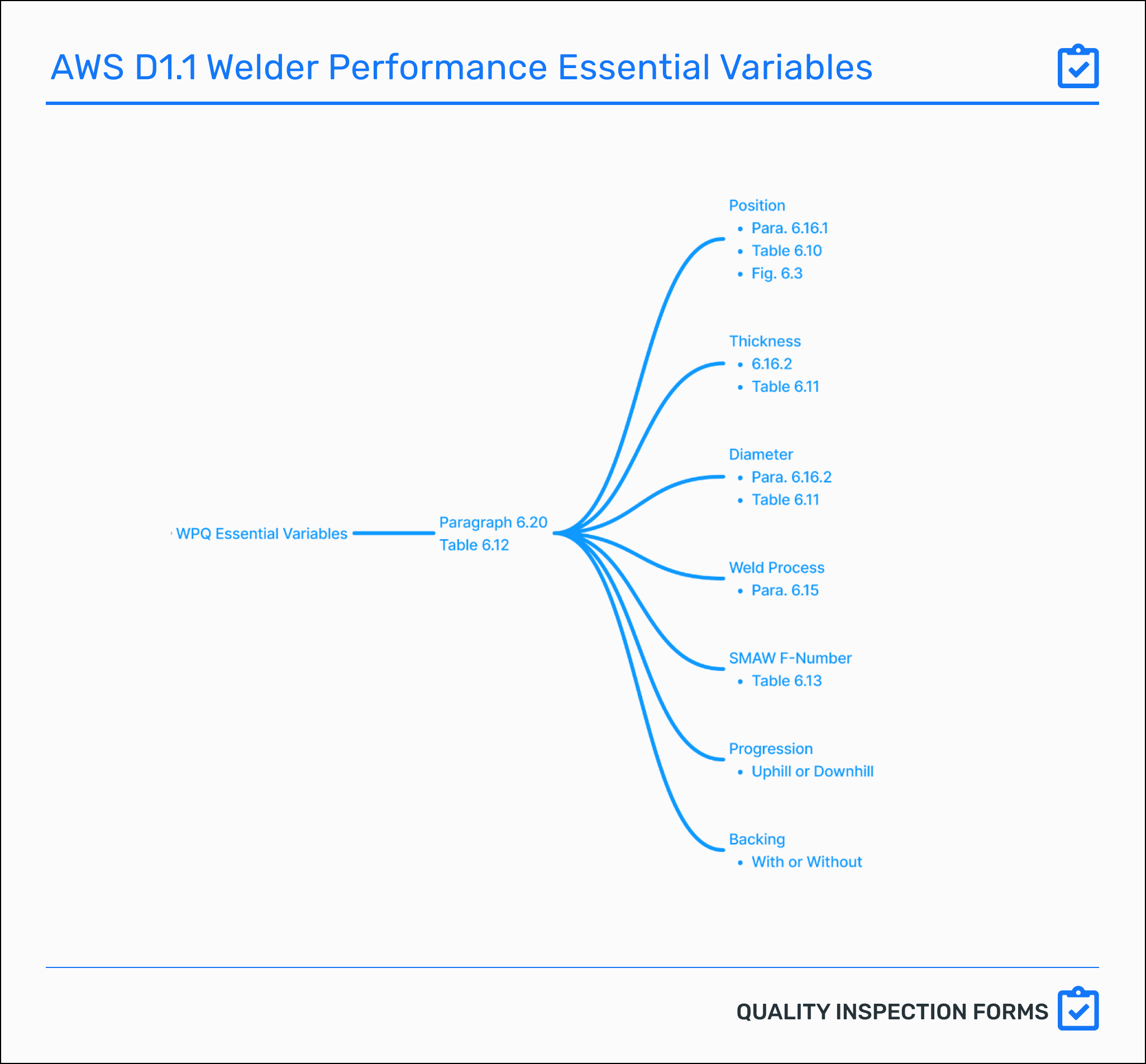

What are the essential variables for a Welder Test?

AWS D1.1 Paragraph 6.20 (refers directly to Table 6.12)

AWS D1.1Table 6.12 : Performance Test Variable Changes that result in Requiring Requalification

Weld Process

SMAW F-Number (Applies to SMAW, but good practice for all weld processes)

Position

Diameter

Thickness

Progression (uphill or downhill) (Welders Only)

Backing (with or without)

Multiple Electrodes (Welding Operators Only)

What are some common plate weld test scenarios?

Limited: restricted position and thickness range, but quick - for short term or novice welders

Actual Values: Flat (1G) test, with backing, on a 3/8” thick plate

Range Qualified: Flat position for grooves, flat + horizontal for fillets, up to 3/4” of thickness

Limited: limited positions & thickness range, average test time, but will cover most work

Actual Values: Vertical (3G) test, with backing, on a 3/8” thick plate

Range Qualified: Flat, horizontal, & Vertical positions for grooves & fillets, up to 3/4” of thickness

Un-limited: all positions, all thickness ranges, longest amount of time, covers all plate work

Actual Values: Vertical (3G) + Overhead (4G) test, with backing, on a 1” thick plate

Range Qualified: All positions for grooves and fillets, and unlimited thickness

What are the dimensions of the welder performance qualification plate materials?

3/8” Plate Test : yields 3/4” Thickness range qualified for the welder

AWS Figure 6.20

Raw Coupon Pieces: 3/8” Thick plate X 3” wide X 7” long (bevel is along the 7” edge)

Backing: 1” wide for bend tests, or 3” wide for RT test

1” Plate Test : yields unlimited thickness range qualified for the welder

AWS D1.1 Figure 6.16

Raw Coupon Pieces: 1” Thick plate X 3” wide X 5” long (bevel is along the 5” edge)

Backing: 1” wide for bend tests, or 3” wide for RT test

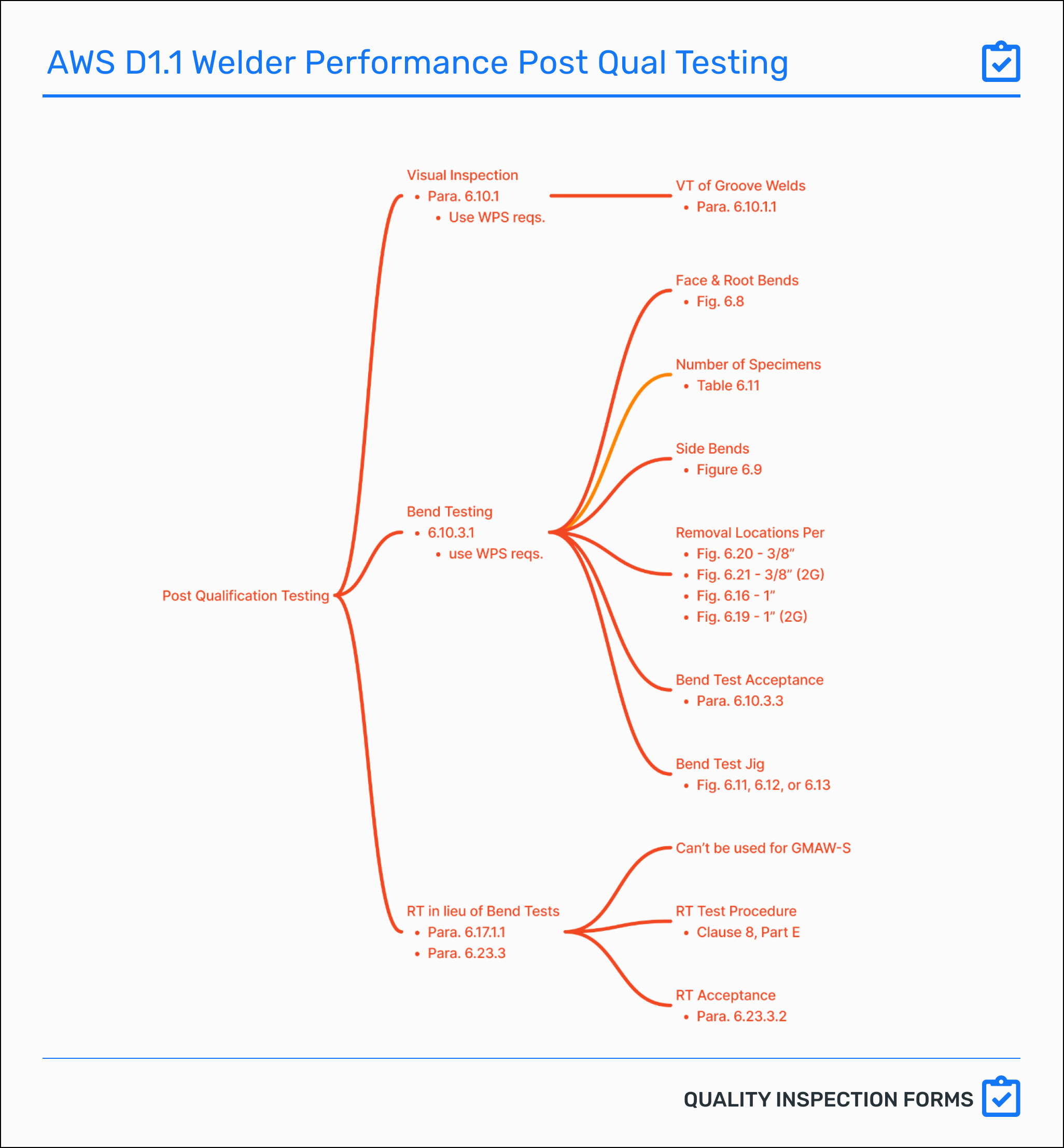

What inspection and testing is required for the completed weld test?

AWS D1.1 Paragraph 6.17 “Type of Qualification Tests Required”

Visual Inspection

See AWS D1.1 6.10.1 (the Performance Test uses the WPS requirements)

This is for the visual inspection of the finished weld (see 6.10.3.3 for bend test acceptance)

AWS D1.1 6.10.1.1 : Visual Inspection of Groove Welds

AWS D1.1 6.10.1.2 : Visual Inspection of Fillet Welds

Face, root, and/or side bends

See AWS D1.1 6.10.3.1 (the Performance Test uses the WPS requirements)

Root and Side Bends : see AWS D1.1 Figure 6.8

Side Bends : see AWS D1.1 Figure 6.9

Bend Test Jigs shall comply with one of the following : AWS D1.1 Figure 6.11, Figure 6.12, or Figure 6.13

See AWS 6.10.3.3 for the visual acceptance criteria for bend tests

See AWS Table 6.11 to determine how many of which type of bend tests are required

RT (radiography testing) in lieu of Bend Tests (Groove Welds)

See AWS D1.1 6.23.3 for general RT of welder performance test

RT Test Procedure and Technique : see AWS D1.1 6.23.3.2 and

RT of Plate : see AWS D1.1 Clause 8 Part E

RT of Tubulars : see AWS D1.1 Clause 10 Part F

RT Acceptance Criteria : See AWS D1.1 8.12.2, except that 8.12.2.2. shall not apply

RT requires a 3” backing bar with no tack welds in the area of interest

See AWS D1.1 Figure 6.16 Note A or 6.20 Note A & B

Some companies will permit RT, some will require bend tests, make sure to understand your application

What do I do if the welder fails his weld test?

Follow the applicable section of AWS D1.1 Paragraph 6.25 for the correct Re-Testing scenario

AWS D1.1 Welder Performance Plate Test Mindmap

D1.1 Welder Performance Test Mindmap

The following sections of AWS D1.1 summarize the primary requirements for qualifying a welder.

Plate : Welder Testing : Clause 6 Part C

Welder Positions Qualified : AWS D1.1 Paragraph 6.16.1 and Table 6.10

Welder Testing Types and Qualified Dimensions : AWS D1.1 Paragraph 6.16.2 and Table 6.11

Required Testing of Coupon : AWS D1.1 Paragraph 6.17 and Table 6.11

Welder Essential Variables : AWS D1.1 Paragraph 6.20 and Table 6.12

Pipe or Tubular Structures : Welder Testing : Clause 10 Part D

Welder Positions Qualified : AWS D1.1 Paragraph 10.16 and Table 10.12

Welder Testing Types and Qualified Dimensions : AWS D1.1 Paragraph 10.16 and Table 10.13

Required Testing of Coupon : AWS D1.1 Paragraph 10.21

Welder Essential Variables : AWS D1.1 Paragraph 6.20 and Table 6.12